In the competitive landscape of modern manufacturing, the selection of appropriate Progressive Die Parts is crucial for enhancing production efficiency and product quality. According to a report by Grand View Research, the global die manufacturing market is projected to reach USD 28.88 billion by 2025, with a compound annual growth rate (CAGR) of 5.9%. This highlights the growing emphasis on advanced manufacturing processes, where the right choice of die components can significantly impact operational costs and overall productivity.

Progressive dies, which allow for the simultaneous processing of multiple operations in a single machine cycle, have transformed traditional manufacturing approaches. The precision and speed facilitated by Progressive Die Parts not only lead to reduced cycle times but also minimize waste, aligning with the principles of lean manufacturing. The Manufacturing Institute indicates that companies employing such efficient systems have reported up to a 25% increase in production efficiency, underscoring the importance of selecting the right parts tailored to specific manufacturing needs.

Choosing the right Progressive Die Parts involves understanding the intricacies of die design, material compatibility, and operational requirements. Industry experts emphasize that manufacturers must consider factors such as tooling longevity, maintenance needs, and production volumes when making their selections. By optimizing these components, manufacturers can achieve a significant competitive edge in an increasingly automated and resource-conscious market.

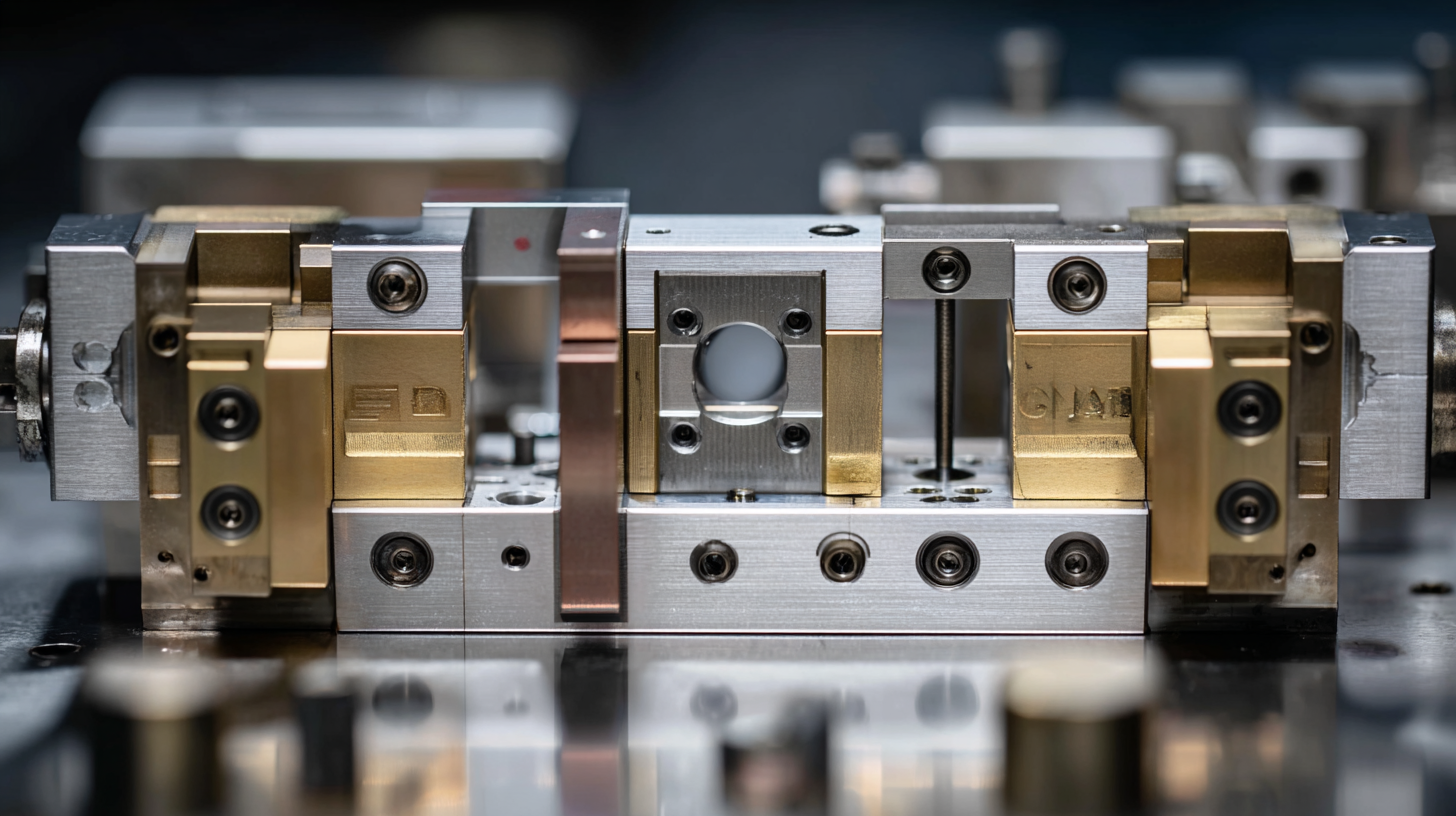

Progressive die parts play a crucial role in the efficiency of manufacturing processes, especially in high-volume production lines. Understanding the basics of these components can significantly enhance workflow and quality. Typically, a progressive die consists of a series of stations, each dedicated to a specific operation such as cutting, shaping, or bending metal. This coordinated sequence allows for the rapid production of complex parts without the need for multiple setups or tools, making it essential to select the right parts that align with the desired specifications.

The functions of progressive die parts can be broken down into several key elements. Firstly, the punch and die sets are instrumental in determining the shape and dimension of the final product, ensuring precision in every stroke. Additionally, guide pins and bushings are vital for maintaining alignment throughout the operation, which helps in achieving consistency. Lastly, the use of springs and adjustable features allows for the accommodation of different materials and thicknesses, thus enhancing the versatility and adaptability of the die. By comprehensively understanding these functions, manufacturers can make informed choices when selecting progressive die parts, ultimately leading to improved operational efficiency and reduced waste.

When selecting materials for progressive die parts, several critical factors must be taken into account to ensure efficiency and longevity in manufacturing processes. First and foremost, the mechanical properties of the materials are paramount. Materials must possess the necessary hardness, tensile strength, and wear resistance to withstand the demanding conditions of progressive stamping. For instance, high carbon steels and tool steels are often preferred due to their superior strength and ability to maintain sharp edges over prolonged usage.

In addition to mechanical properties, the compatibility of the materials with the specific manufacturing environment should also be evaluated. Factors such as corrosion resistance and thermal stability can significantly impact the performance of die parts, particularly in environments that involve moisture or extreme temperatures. Furthermore, considerations regarding manufacturability and cost-effectiveness are essential. Selecting materials that are not only readily available but also economical can contribute to more streamlined production processes and better overall project viability. By carefully analyzing these factors, manufacturers can make informed decisions that enhance the efficiency and effectiveness of their progressive die operations.

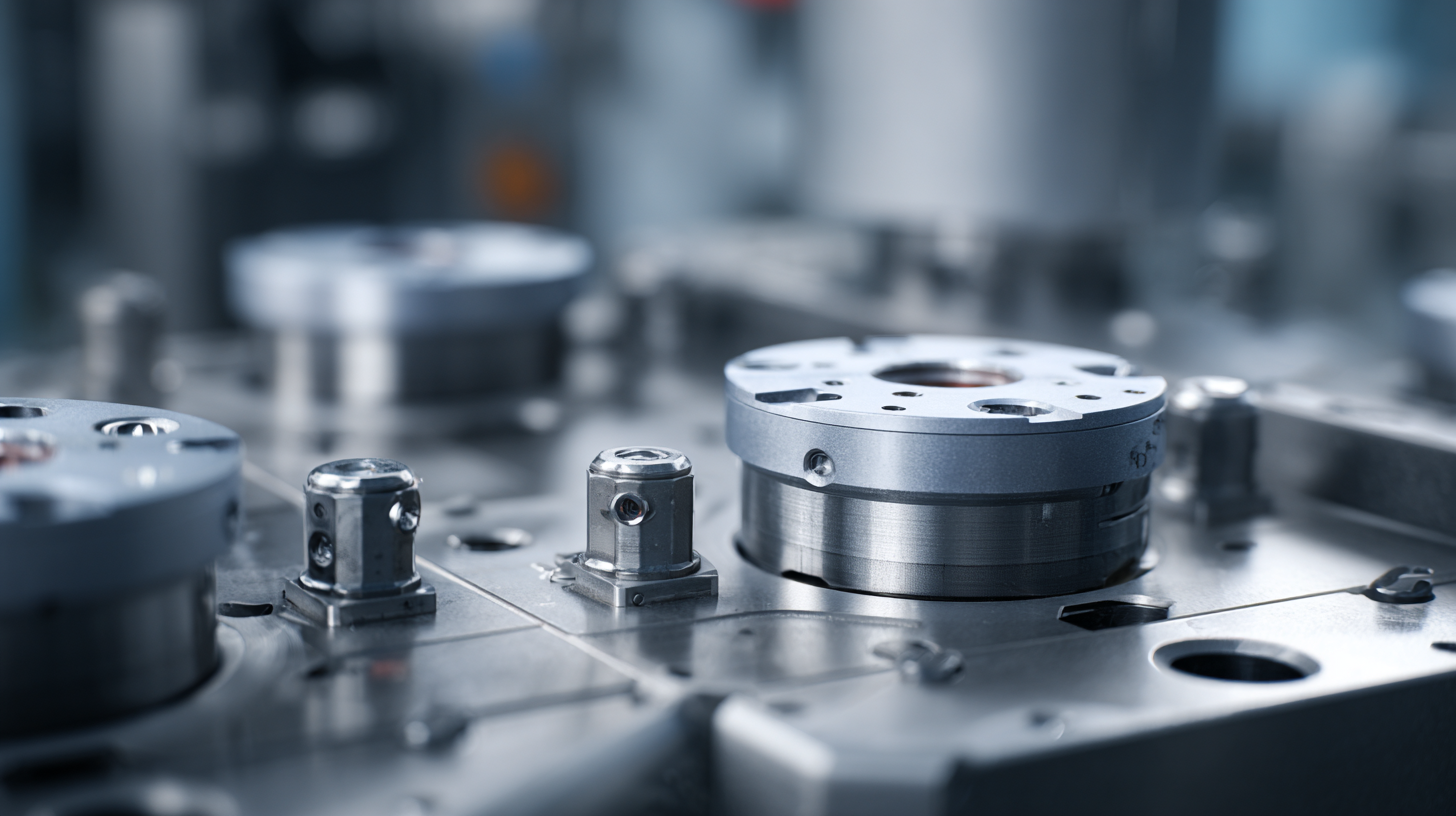

When evaluating design features that enhance manufacturing efficiency in progressive die parts, it is essential to consider factors such as material selection, tooling precision, and die configuration. A study by the Manufacturers Alliance for Productivity and Innovation (MAPI) indicated that optimizing material properties can reduce production costs by up to 20%, directly impacting overall manufacturing efficiency. For instance, using high-strength, lightweight alloys can help minimize wear and extend the lifespan of die components, ultimately leading to fewer downtimes and increased productivity.

Moreover, the precision of tooling is a crucial aspect to focus on. Reports from the National Tooling and Machining Association (NTMA) highlight that improving tooling accuracy by just 10% can increase output by as much as 15%. Features such as self-lubricating mechanisms and advanced cooling systems can significantly reduce friction and thermal stress, allowing for smoother operation and faster cycle times. By integrating smart design principles that focus on these key areas, manufacturers can create more efficient processes and achieve higher quality outputs with minimal waste.

Choosing the right progressive die parts is crucial for maintaining efficient manufacturing processes, but equally important is the effective maintenance and replacement of these components. Regular inspection and routine maintenance of die parts can help identify wear and tear early, which prevents costly downtime and production delays. Ensuring that parts are cleaned, lubricated, and aligned correctly can significantly extend their lifespan and maximize operational efficiency.

When it comes to replacing progressive die parts, it’s important to consider compatibility with existing components and overall design requirements. Selecting high-quality replacement parts can make a significant difference in performance. Moreover, as external factors like tariffs may affect material costs and availability, staying informed on market conditions is vital. Businesses should prioritize establishing strong relationships with reliable suppliers to ensure quick access to necessary parts, reducing downtime and supporting continued efficiency in manufacturing processes.

| Part Name | Material | Common Issues | Maintenance Tips | Replacement Frequency |

|---|---|---|---|---|

| Punch | Tool Steel | Chipping and Wear | Regular Inspection and Sharpening | Every 5000 Cuts |

| Die Insert | HSS (High-Speed Steel) | Overheating and Cracking | Cooling and Lubrication | Every 3000 Cuts |

| Guide Pins | Stainless Steel | Misalignment | Keep Lubricated and Aligned | Every 10000 Cuts |

| Strippers | Aluminum | Sticking and Wear | Regular Cleaning and Adjustment | Every 2000 Cuts |

| Ejectors | Carbon Steel | Failure to Eject | Inspect Springs and Guides | Every 5000 Cuts |

When selecting progressive die components, it is crucial to avoid common mistakes that can hinder efficiency and productivity in manufacturing processes. One typical error is underestimating the importance of material selection. Choosing the wrong materials can lead to premature wear and tear on die parts, resulting in frequent replacements and downtime. Always consider the properties of the materials, such as strength and durability, and ensure they are compatible with the specific manufacturing requirements.

Another frequent mistake is failing to consider the intended application context. Many manufacturers choose die components based solely on cost without analyzing their suitability for the task at hand. This short-sighted approach can lead to eventual inefficiencies and higher long-term costs. It's essential to evaluate factors like part complexity, operational speed, and production volume to select components that will perform optimally in their intended applications. Proper choices in design and function will significantly enhance manufacturing efficacy, reducing errors and improving overall output.