In the ever-evolving landscape of modern vehicle design, the significance of Automotive Metal Stamping Parts cannot be overstated. According to a report by Grand View Research, the global automotive stamping market size is expected to reach USD 25.16 billion by 2025, underscoring the increasing reliance on precision-engineered components to enhance vehicle performance and aesthetics. Automotive Metal Stamping Parts not only contribute to the structural integrity and safety of vehicles but also play a pivotal role in lightweighting initiatives that improve fuel efficiency and reduce emissions. As automakers increasingly focus on sustainability while meeting stringent regulatory standards, the demand for high-quality stamped components continues to grow, fostering innovation and technological advancements in the industry. This evolution is essential for manufacturers looking to remain competitive in a rapidly changing automotive landscape.

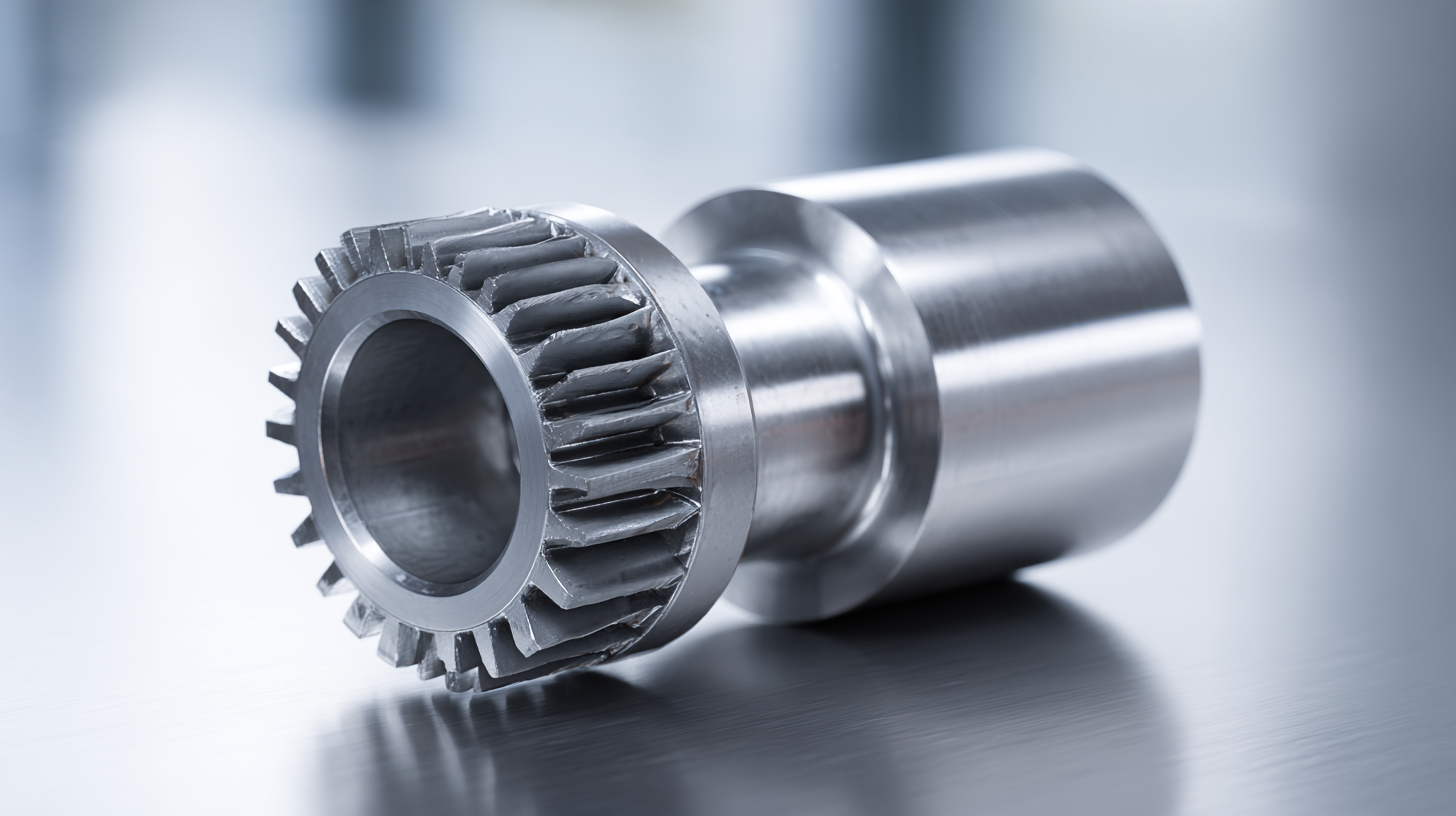

In modern vehicle design, automotive metal stamping parts play a crucial role in achieving lightweight structures, which are essential for meeting regulatory standards and consumer demands for fuel efficiency. The traditional approach to vehicle construction emphasized durability and strength, often resulting in heavier vehicles. However, advancements in metal stamping technology have enabled manufacturers to create intricate and robust components from materials such as high-strength steel and aluminum, significantly reducing overall vehicle weight without compromising safety or performance.

The impact of automotive metal stamping on lightweight vehicle design extends to various aspects, including the optimization of structural components like A, B, C, and D pillars. These pillars not only provide essential structural integrity but also contribute to the vehicle’s crashworthiness. By utilizing lightweight materials and innovative stamping techniques, automakers can create pillars that offer optimal support while minimizing weight. This shift towards lighter construction is critical in the automotive industry's ongoing quest to achieve sustainability, improve fuel efficiency, and meet the growing carbon neutrality goals across the globe.

| Part Type | Material | Weight (kg) | Strength (MPa) | Application |

|---|---|---|---|---|

| Chassis Components | High-strength Steel | 50 | 350 | Frame Structure |

| Body Panels | Aluminum | 30 | 210 | Outer Skin |

| Engine Components | Stainless Steel | 25 | 300 | Engine Mounting |

| Suspension Parts | Carbon Steel | 40 | 400 | Control Arms |

Metal stamping has become an integral component in modern automotive engineering, delivering several key benefits that enhance vehicle design, performance, and efficiency. According to a report by Markets and Markets, the global automotive stamping market is projected to reach $30.48 billion by 2026, growing at a CAGR of 5.3%. This growth reflects the increasing adoption of metal stamping parts due to their precision and cost-effectiveness. By utilizing high-strength materials, manufacturers can create lightweight components that contribute to improved fuel efficiency and reduced CO2 emissions, aligning with global sustainability goals.

One significant advantage of metal stamping is its ability to produce complex geometries with high repeatability. This is particularly crucial as automotive designs become more intricate to meet both aesthetic and functional demands. A study published by the International Journal of Automotive Engineering highlights that stamped parts can achieve tolerances as tight as ±0.02 mm, which is essential for maintaining the performance and safety standards of modern vehicles. Additionally, advancements in automated stamping technologies have further enhanced the throughput and quality of these components, leading to greater efficiency in the manufacturing process while minimizing waste. As the automotive industry continues to evolve, the reliance on metal stamping parts is expected to grow, playing a vital role in driving innovation and enhancing vehicle performance.

The automotive industry is witnessing a significant transformation with the integration of advanced metal stamping techniques, driven by modern demands for precision and efficiency. Recent innovations, particularly in machine learning, are enhancing the accuracy of sheet metal forming processes. By employing models that utilize light gradient boosting machine algorithms in conjunction with deep neural networks, manufacturers can achieve higher levels of consistency in part production, reducing waste and improving overall quality.

Tips for manufacturers looking to implement these advanced techniques include investing in training for personnel on the latest machine learning applications and continuously evaluating the performance of their metal stamping equipment. Furthermore, embracing technologies like automated sorting systems for scrap metal can aid in streamlining operations and maximizing resource recovery. As the global CNC machine market expands, staying ahead of industry trends will be crucial for competitive advantage.

The role of automotive metal stamping parts is becoming increasingly critical, with innovations like precise aluminum alloy sorting enabling manufacturers to better leverage materials. This not only enhances product quality but also supports sustainability efforts through effective recycling processes. As technological advancements continue to shape the future of automotive design, it is essential for stakeholders to remain agile and adaptive to new possibilities in metal stamping methodologies.

As the automotive industry pivots towards electric vehicles (EVs), stamped automotive parts play an increasingly essential role in modern vehicle design. The evolution of battery chemistries necessitates new designs and materials that can optimize both performance and cost. With the global automotive market projected to reach approximately USD 6.68 trillion by 2032, the demand for efficient manufacturing processes, such as metal stamping, will be critical in meeting the growing needs of the electric vehicle sector.

Tips: When considering the integration of stamped parts in EV design, focus on weight reduction and structural integrity. Choosing advanced materials can enhance overall vehicle efficiency and improve battery performance. Additionally, leveraging artificial intelligence (AI) in manufacturing can streamline production processes, enabling companies to stay competitive in a rapidly evolving market.

Amidst this transition, traditional automakers must adapt their strategies, navigating the shift toward zero-emission technologies. With trends indicating a persistent rise in the adoption of electric vehicles, companies that embrace innovation in stamped automotive parts will not only enhance their product offerings but also ensure compliance with future regulations aimed at reducing carbon footprints. Investing in cutting-edge stamping technologies can lead to significant advancements in vehicle design, making it more crucial than ever for manufacturers to stay ahead of these trends.

This chart illustrates the impact rating of various factors related to automotive metal stamping parts in modern vehicle design. The scores reflect the significance of stamping process efficiency, the adoption rate of electric vehicles, material cost considerations, design complexity, and production volume on the automotive industry.

The automotive industry is increasingly leveraging metal stamping to enhance vehicle performance, driven by a need for efficiency in both design and production. The global automotive metal stamping market is projected to grow at a CAGR of 5.1%, underscoring the vital role this process plays in modern vehicle engineering. By utilizing various stamping techniques like deep drawing and bending, manufacturers can create lightweight components without sacrificing strength. This is particularly crucial as the industry shifts towards more fuel-efficient and environmentally friendly vehicles.

One notable study focused on lightweight steel door design resulted in a weight reduction of over 5 kg, equating to more than 25% savings, all while maintaining cost parity with the original manufacturing methods. Such advancements not only enhance the overall efficiency of the vehicle but also contribute significantly to performance improvements, such as increased agility and better fuel economy. Moreover, as EV battery packs evolve with higher voltages and energy densities, the demand for innovative metal stamping solutions continues to rise, aligning with the industry's commitment to sustainability and innovation.

One notable study focused on lightweight steel door design resulted in a weight reduction of over 5 kg, equating to more than 25% savings, all while maintaining cost parity with the original manufacturing methods. Such advancements not only enhance the overall efficiency of the vehicle but also contribute significantly to performance improvements, such as increased agility and better fuel economy. Moreover, as EV battery packs evolve with higher voltages and energy densities, the demand for innovative metal stamping solutions continues to rise, aligning with the industry's commitment to sustainability and innovation.