In the world of metal stamping, the functionality of Progressive Die Parts plays a crucial role in enhancing production efficiency and precision. According to a report by Grand View Research, the global metal stamping market is projected to reach $280 billion by 2025, driven largely by advancements in manufacturing technologies and demand for complex components. Progressive dies, known for their ability to perform multiple operations in a single pass, are pivotal in achieving high-quality outputs while minimizing waste. As manufacturers strive for greater productivity, understanding the nuances of Progressive Die Parts becomes essential. This guide aims to provide beginners with a comprehensive look into these components, equipping them with the knowledge needed to navigate the intricacies of progressive die systems in today's competitive landscape.

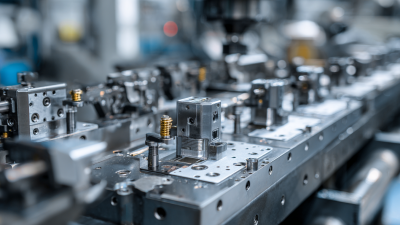

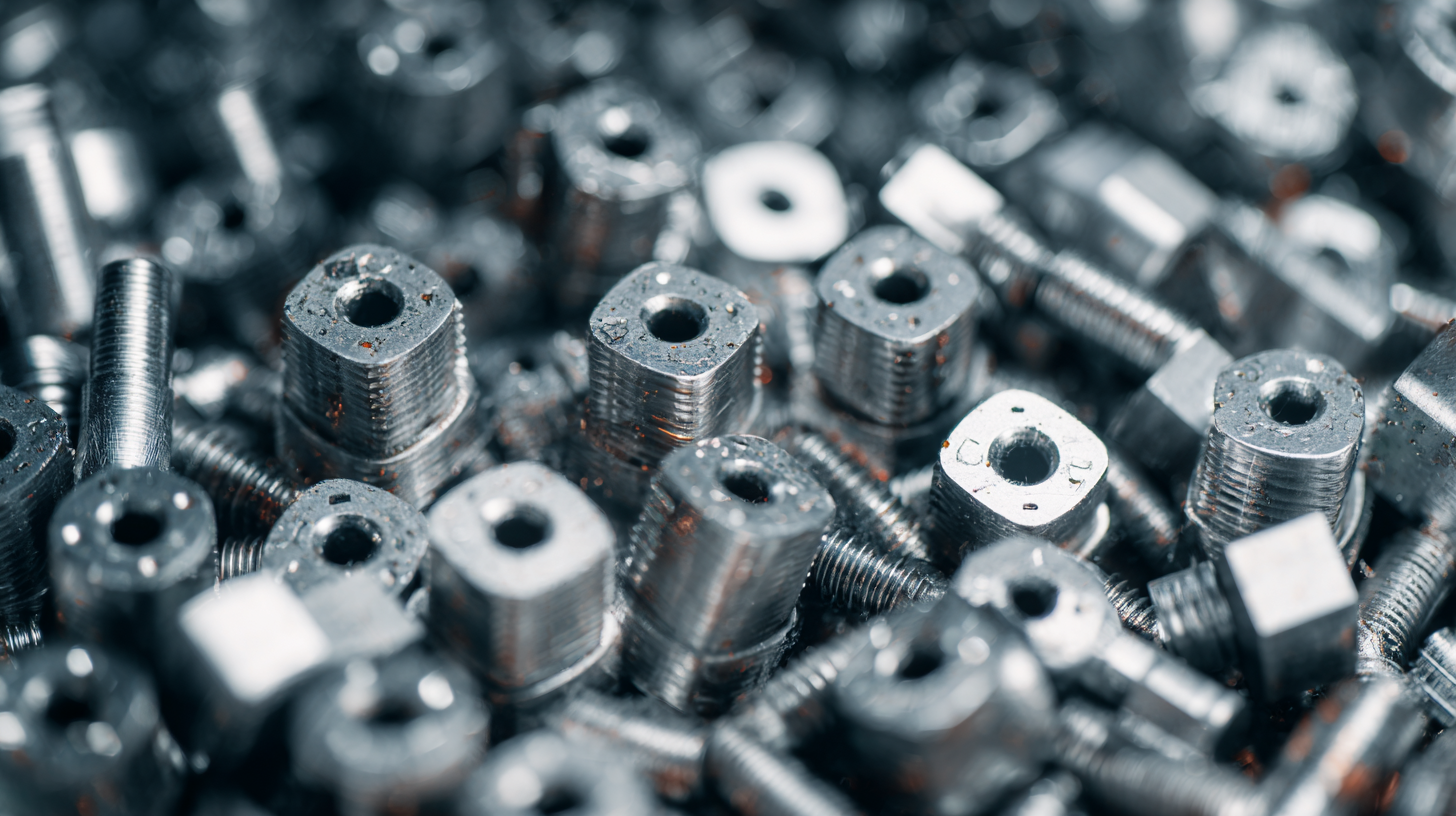

Progressive die parts play a crucial role in the manufacturing process, particularly in the field of metal forming. At its core, a progressive die is a specialized tool used in sheet metal fabrication, where multiple operations are performed in a single die as the material passes through it. This allows for high efficiency and precision, making it ideal for producing large quantities of parts with tight tolerances. The process typically involves a series of stations through which the strip of metal travels, with each station performing a specific function such as cutting, bending, or stamping.

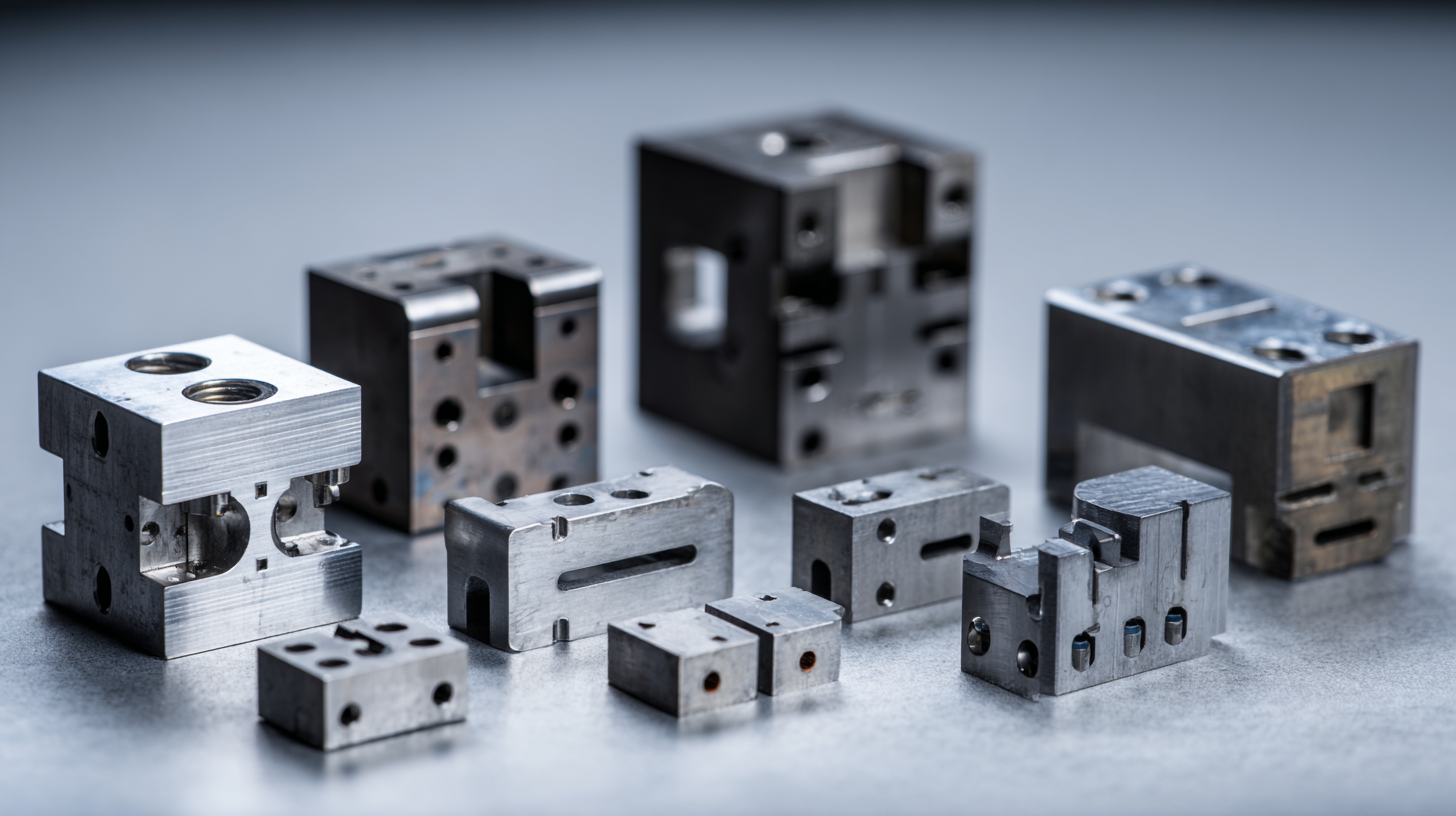

Understanding the basics of progressive die parts is essential for anyone looking to delve into the world of manufacturing. These parts can vary significantly in design and purpose, reflecting the complexity of the components they help create. Common elements include punch and die assemblies, which work together to shape the material, as well as guides that ensure the metal strip moves correctly through the die. By mastering the fundamentals of how these components interact, beginners can appreciate their pivotal role in streamlining production and enhancing the overall quality of manufactured goods.

Progressive dies play a crucial role in the manufacturing industry, particularly in metal stamping operations.

Understanding the key types of progressive die components and their respective functions is essential for beginners looking to enhance their knowledge in this field.

The primary components include the die frame, punches, and dies, each serving distinct purposes.

The die frame provides structural integrity and support for various components, while punches are responsible for cutting or shaping the material.

According to a recent report by the Metal Stamping Association, the efficiency of a well-designed progressive die can increase production rates by up to 50%, showcasing the importance of understanding each component's function.

Progressive dies play a crucial role in the manufacturing industry, particularly in metal stamping operations.

Understanding the key types of progressive die components and their respective functions is essential for beginners looking to enhance their knowledge in this field.

The primary components include the die frame, punches, and dies, each serving distinct purposes.

The die frame provides structural integrity and support for various components, while punches are responsible for cutting or shaping the material.

According to a recent report by the Metal Stamping Association, the efficiency of a well-designed progressive die can increase production rates by up to 50%, showcasing the importance of understanding each component's function.

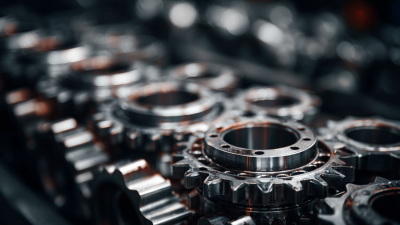

Additionally, elements like guide pins and bolsters are vital for proper alignment and stability during the stamping process. Guide pins ensure that the die sets remain correctly aligned throughout the operation, preventing misalignment that can lead to defects. Bolsters support the entire stamping mechanism, distributing forces evenly to enhance durability. The Total Manufacturing Productivity Index (TMPI) highlights that companies utilizing advanced progressive die systems report a 20% decrease in material waste due to the precision offered by these components. By familiarizing oneself with these fundamental elements, beginners can better appreciate the intricacies of progressive die functionality and their impact on overall manufacturing efficiency.

When working with progressive dies, selecting the right tools and equipment is crucial for achieving optimal results. Progressive dies are designed to perform multiple operations in a single pass, making them essential for high-volume manufacturing. The most important equipment to consider includes reloading presses, which greatly enhance the efficiency of the die work. Understanding the types of presses available—such as single-stage, turret, and progressive—will aid beginners in making informed choices tailored to their specific needs. Each type offers unique benefits that can significantly impact production speed and accuracy.

In addition to presses, other essential tools include die maintenance equipment, such as cleaning solvents and lubricants, which help to ensure longevity and reliable performance. Additionally, investment in quality measuring tools is necessary to maintain precision and consistency throughout the production process. For those new to working with progressive dies, familiarizing oneself with these essential tools will pave the way for successful outcomes and a deeper understanding of the die-making process. Embracing these components allows manufacturers to meet rising demand for quick, high-quality outputs in a competitive landscape.

Progressive die parts play a crucial role in modern manufacturing, enabling the automated production of complex components with high precision. One of the most common applications of these parts is in the automotive industry, where they are used to create various metal components such as brackets, clips, and housings. The efficiency of progressive dies allows manufacturers to produce large volumes of parts quickly while maintaining consistency and accuracy in dimensions, which is vital for maintaining quality standards in vehicle assembly.

Progressive die parts play a crucial role in modern manufacturing, enabling the automated production of complex components with high precision. One of the most common applications of these parts is in the automotive industry, where they are used to create various metal components such as brackets, clips, and housings. The efficiency of progressive dies allows manufacturers to produce large volumes of parts quickly while maintaining consistency and accuracy in dimensions, which is vital for maintaining quality standards in vehicle assembly.

Another significant application of progressive die parts can be found in the electronics sector. Here, they are instrumental in fabricating intricate components for devices like smartphones and computers. These parts facilitate the mass production of thin, lightweight metal elements that are essential for connectors, casings, and circuit boards. The ability to make multiple cuts and forms in a single pass not only optimizes production time but also reduces material waste, making progressive die technology an eco-friendly choice in manufacturing processes.

Progressive dies are essential tools in metal stamping, allowing for efficient and complex part production in a single continuous operation. For beginners, understanding how to maintain these dies is critical to ensuring longevity and optimal performance. According to industry reports, effective die maintenance can extend the lifespan of tooling by up to 50%, translating to substantial cost savings for manufacturing operations.

Tips for Beginners: Best Practices for Maintaining Progressive Dies

To maintain your progressive dies effectively, start with regular cleaning. Accumulated debris can lead to misalignment and increased wear. It’s advisable to use non-abrasive cleaning agents that are suitable for the specific materials of your dies. Additionally, ensure that lubrication is applied according to guidelines; proper lubrication reduces friction and heat, which are primary factors in die wear.

Another crucial aspect of die maintenance is routine inspection for any signs of wear or damage. Early detection can prevent larger issues that may disrupt production. Keeping spare parts on hand for quick replacements can also minimize downtime. By implementing these practices, you can enhance the efficiency of progressive dies, paving the way for successful production runs and consistent output quality.