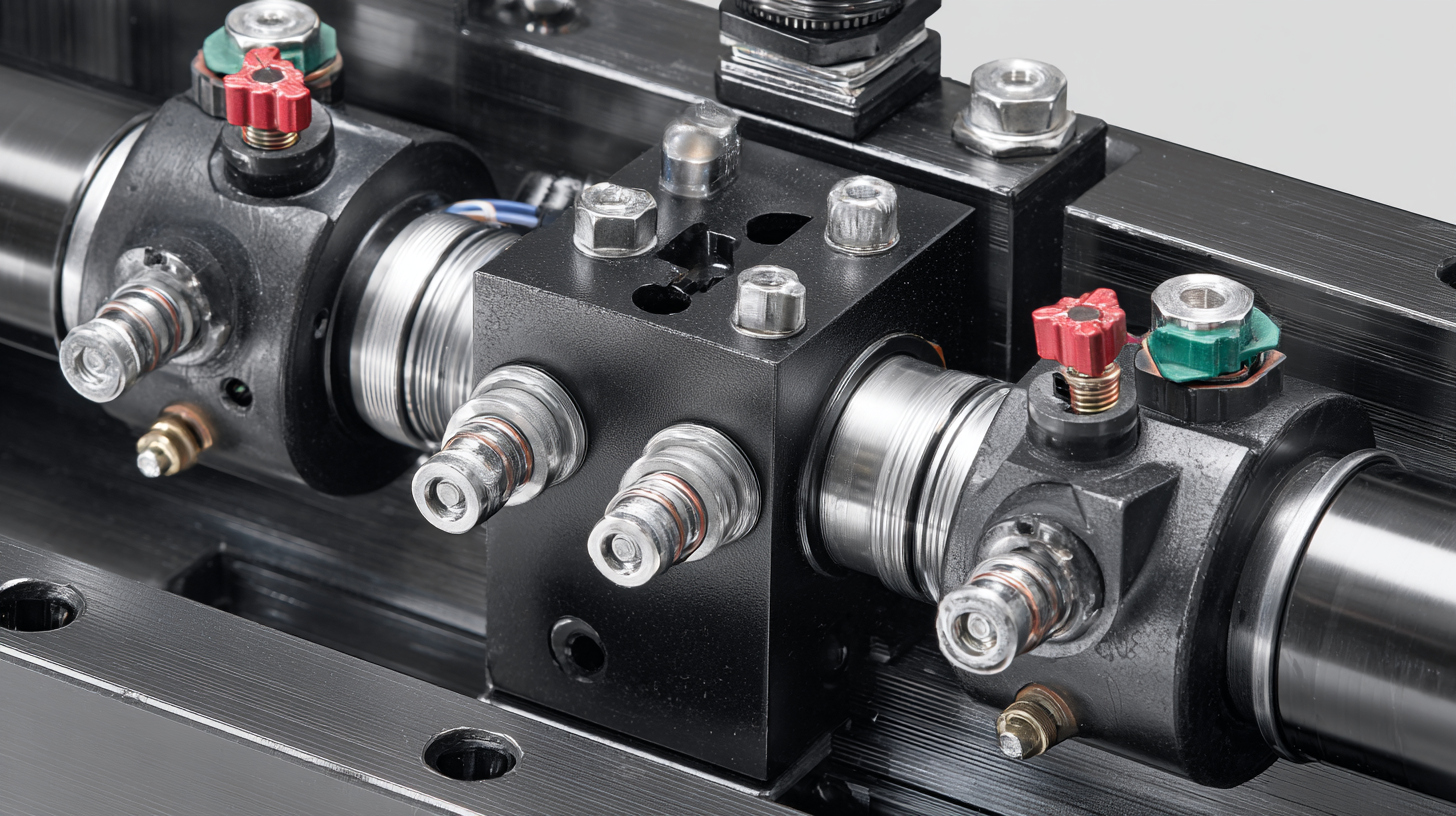

Hydraulic seals are critical components in fluid power systems, playing a vital role in maintaining efficiency and preventing leaks in hydraulic machinery. According to recent industry reports, the global hydraulic seals market is projected to reach $12 billion by 2026, highlighting their importance in various sectors, including manufacturing, automotive, and construction. These seals ensure proper sealing during the compression and movement of hydraulic fluids, which is essential for optimal system performance.

In a world where energy efficiency and sustainability are paramount, understanding hydraulic seals becomes increasingly crucial as they contribute to reducing the operational costs and enhancing the reliability of fluid power systems. This guide aims to delve into the fundamentals of hydraulic seals, elucidating their types, applications, and maintenance, thus empowering professionals and engineers to make informed decisions in their hydraulic system designs.

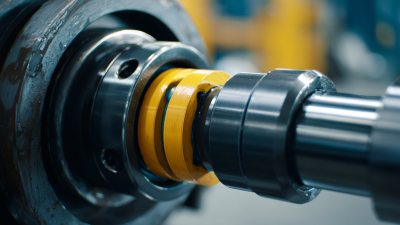

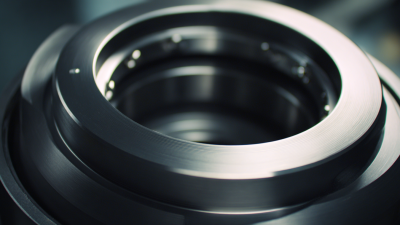

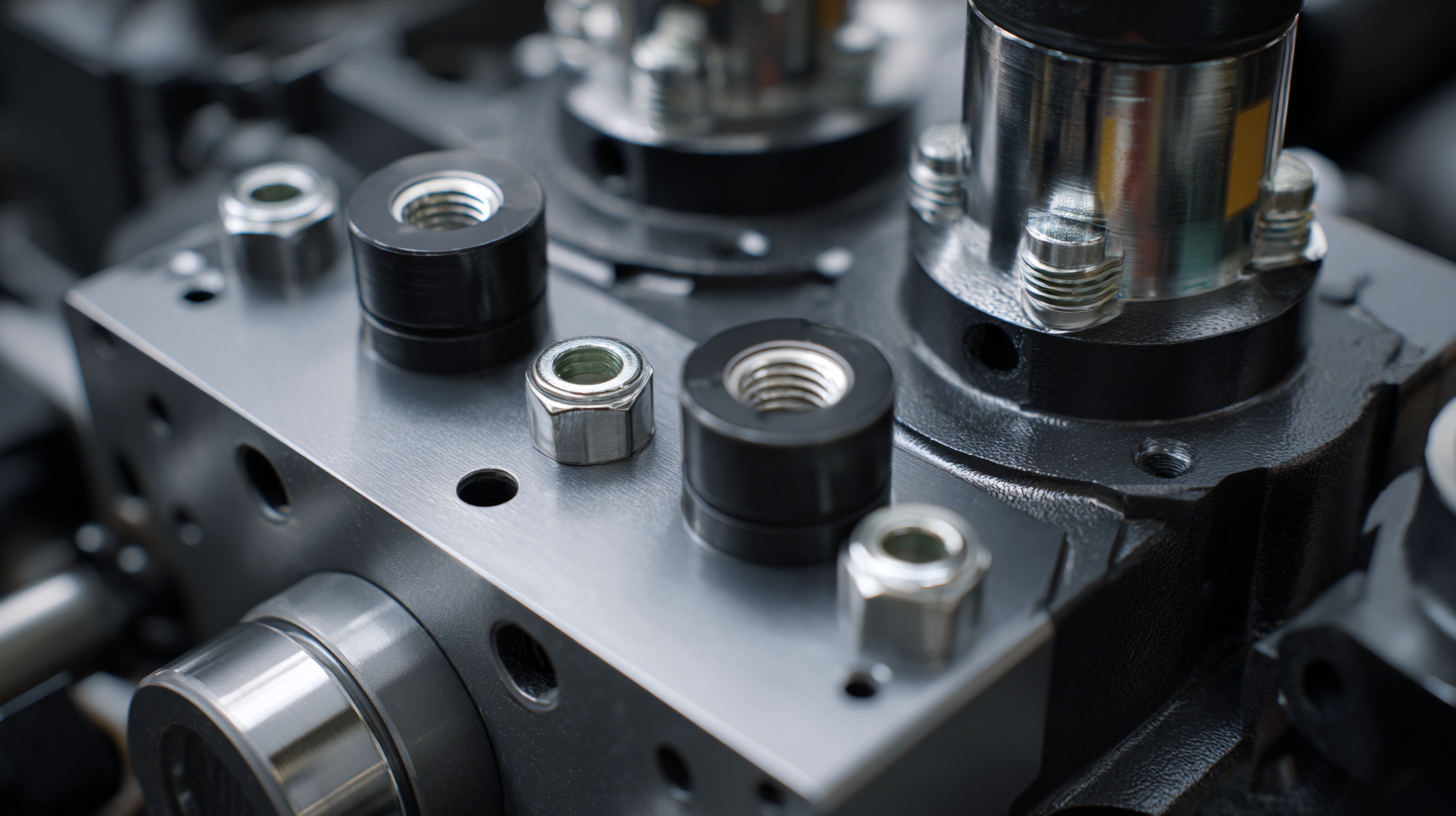

Hydraulic seals play a critical role in fluid power systems by ensuring the efficient operation of machinery and preventing leaks. There are various types of hydraulic seals, each suited to different applications and environments. Common types include O-rings, rod seals, and piston seals. O-rings are versatile and used for static applications, while rod seals are designed for dynamic applications, providing a tight seal around moving components. Piston seals, on the other hand, are essential in maintaining pressure within hydraulic cylinders, making them vital for tasks requiring high force output.

When choosing the right seal for your system, consider the operating conditions such as pressure, temperature, and fluid type. This knowledge can help you avoid costly downtimes due to seal failure.

Tips: Regularly inspect seals for wear and damage, as early detection can significantly extend their lifespan. Additionally, ensure that seals are installed correctly to prevent leaks and maintain system efficiency. Keeping your hydraulic fluid clean is another way to prolong the life of your seals, as contaminants can lead to premature failure.

Hydraulic seals play a critical role in the efficiency and longevity of fluid power systems. Key performance metrics include leakage control, wear resistance, and operating temperature limits. Effective sealing solutions minimize fluid leakage, which not only enhances the overall system efficiency but also conserves resources and reduces environmental impact. The materials and design of hydraulic seals are pivotal in determining their ability to withstand varying pressures and temperatures without compromising performance.

Several factors influence the longevity and efficiency of hydraulic seals. Primarily, the compatibility of seal materials with the specific fluids used in the application impacts their durability. Chemical resistance is vital, as aggressive fluids can degrade seals more rapidly. Additionally, installation procedures and the operating environment, including exposure to contaminants and operational vibrations, can significantly affect seal performance. Regular maintenance and monitoring can address wear and prevent failure, ensuring the reliability of fluid power systems and extending the life of hydraulic seals.

Material selection plays a crucial role in determining the performance and longevity of hydraulic seals in fluid power systems. According to a report by the Fluid Power Institute, approximately 40% of seal failures can be attributed to inappropriate material choices.

Different environments, such as high temperatures or abrasive conditions, require specific seal materials to ensure optimal performance. For instance, nitrile rubber (NBR) is often used for its excellent resistance to petroleum-based oils, while fluorocarbon elastomers excel in high-temperature applications, offering stability up to 400°F (204°C) without degrading.

Moreover, the compatibility of seal materials with various fluids cannot be overlooked. When dealing with water-based fluids or bio-degradable oils, a shift to thermoplastic elastomers (TPE) may be necessary to maintain seal integrity and reduce the likelihood of swelling or shrinkage. A recent study from the National Fluid Power Association highlights that using the right material can improve seal life by more than 50%, significantly reducing maintenance costs and system downtime. As industries continue to evolve, understanding the material implications is essential for optimizing hydraulic seal performance across diverse applications.

Hydraulic seals play a crucial role in ensuring the efficiency and reliability of fluid power systems. However, these seals often face common challenges that can affect system functionality. One major issue is wear and tear caused by friction and poor lubrication, which can lead to leaks or seal failure. Additionally, environmental factors such as temperature fluctuations and exposure to contaminants can compromise the integrity of hydraulic seals.

To address these challenges, regular maintenance and monitoring are essential. One effective tip is to implement a routine inspection schedule that checks for signs of wear and potential leaks. This proactive approach can help identify issues before they escalate, ensuring that the hydraulic system operates smoothly.

Another important tip is to choose the right seal material that matches the specific operating conditions of your hydraulic system. For example, seals made from fluoroelastomer are ideal for high-temperature applications, while polyurethane seals offer excellent resistance to wear. By selecting appropriate materials and maintaining your seals regularly, you can enhance the lifespan of your hydraulic system and optimize its performance.

The future of hydraulic seals is poised for significant advancements, driven by the demand for enhanced performance in fluid power applications. Innovations such as advanced materials and smart technology integration are set to revolutionize how these components function. For instance, the development of high-performance elastomers can provide greater resistance to wear, temperature fluctuations, and aggressive fluids, thereby extending the lifespan of hydraulic seals and improving overall system reliability.

Tip: When selecting hydraulic seals for your applications, consider the specific conditions they will encounter, such as temperature and pressure ranges, to ensure optimal performance.

Another exciting trend is the incorporation of sensors within seals to monitor conditions in real-time. This innovation can lead to proactive maintenance strategies, reducing downtime and operational costs. By analyzing data on seal performance and wear, companies can optimize their fluid power systems for increased efficiency and sustainability.

Tip: Regularly inspect and maintain hydraulic seals, as early detection of wear or damage can prevent costly repairs and system failures.