Stamped Sheet Metal is an essential component in various industries, owing to its versatility and efficiency. This manufacturing process involves shaping metal sheets into precise forms using a stamping press, making it a popular choice for producing components with intricate designs. From automotive and aerospace to household appliances and electronic devices, Stamped Sheet Metal plays a crucial role in ensuring functionality and durability in numerous applications.

One of the key benefits of Stamped Sheet Metal is its ability to create highly detailed parts with minimal waste, which leads to cost-effective production. This technique allows for uniformity and reproducibility, making it ideal for mass production. Furthermore, the materials used in stamping can include various metals like aluminum, steel, and copper, providing designers with a wide range of options to choose from based on their specific requirements.

In conclusion, understanding the significance of Stamped Sheet Metal not only highlights its advantages but also showcases its integral role in modern manufacturing. As industries continue to evolve, the demand for such precise and reliable manufacturing methods will only grow, further solidifying the position of Stamped Sheet Metal as a cornerstone of production.

Stamped sheet metal is a crucial component in various industries, defined as metal sheets that have been shaped and cut into specific forms through a process of stamping. This process involves the use of dies and presses, which enable the transformation of flat sheets into intricate geometries with high precision. According to industry reports, the global metal stamping market was valued at approximately $21 billion in 2020, and it is projected to reach around $29 billion by 2027, reflecting a steady growth rate driven by demand in automotive, aerospace, and electronics sectors.

One of the key benefits of stamped sheet metal is its versatility. Stamped components can be crafted into numerous shapes, effectively accommodating the diverse design requirements in manufacturing. The process also minimizes waste material, making it a cost-effective option for producing large volumes of parts. Data from the Metal Stamping Association indicates that manufacturers can achieve a material utilization rate of up to 90% through optimized stamping techniques. Additionally, the thin nature of sheet metal allows for lightweight solutions, which is critical in applications where reducing weight can lead to improved energy efficiency and performance.

The applications of stamped sheet metal are extensive, ranging from automotive body panels to electronic enclosures. In the automotive industry, for instance, approximately 75% of a typical car's body is formed from stamped metal, showcasing the integral role it plays in structural integrity and aesthetics. As industries continue to innovate, the demand for high-quality stamped components will likely increase, further solidifying the significance of stamped sheet metal in modern manufacturing practices.

Sheet metal stamping is a crucial process in the manufacturing sector, encompassing various techniques to transform flat metal sheets into intricate components. The primary manufacturing processes involved in sheet metal stamping include blanking, punching, and bending. Blanking involves cutting out flat shapes from the sheet metal, which serves as a precursor to other processes. This stage is critical for ensuring precision and accuracy in the final part dimensions.

Punching, on the other hand, creates holes or cutouts in the metal sheets, which can be used for assembly or functionality in the finished product. This process often utilizes a punching press that exerts high force through a die, producing clean and consistent holes. Bending is another essential process, where the sheet metal is manipulated into desired angles or forms, enhancing its structural integrity and allowing for more complex designs. Together, these processes enable manufacturers to produce high-quality stamped metal parts suited for diverse applications across industries, from automotive to electronics.

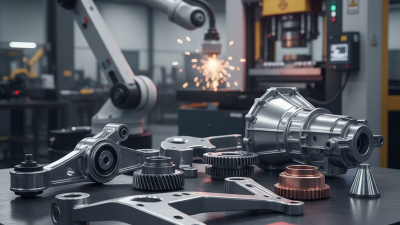

Stamped sheet metal is increasingly becoming a cornerstone in various industries due to its unique advantages. This manufacturing process involves creating metal components by deforming flat sheet metal into desired shapes using a die. Reports indicate that the global sheet metal fabrication market is anticipated to reach $24.45 billion by 2027, driven by its versatility and efficiency in production. The automotive industry, for instance, leverages stamped components for chassis, body panels, and structural elements, benefiting from the material’s lightweight nature that contributes to fuel efficiency and overall performance.

In the aerospace sector, stamped sheet metal plays a critical role in producing complex parts that require high strength-to-weight ratios. For example, aluminum alloys, often used in aerospace applications, can be stamped into intricate designs while maintaining structural integrity. A report by MarketsandMarkets notes that the aerospace components market is projected to grow at a CAGR of 4.3%, indicating a strong demand for standardized yet customized stamped parts. Furthermore, industries such as HVAC, electronics, and construction also benefit from stamped sheet metal, as it allows for rapid scalability in production, lower material waste, and cost-effectiveness, which are crucial in today's competitive market landscape.

Stamped sheet metal has become an integral component in various engineering sectors due to its versatility and efficiency in manufacturing. This process involves shaping metal sheets into desired forms through cutting, bending, and stamping methods. Industries such as automotive, aerospace, and electronics have widely adopted stamped sheet metal for its lightweight, strength, and cost-effectiveness. According to a report by Grand View Research, the global sheet metal market is projected to reach USD 243.80 billion by 2025, with a significant portion attributed to stamped products, highlighting the growing demand for these materials in modern engineering applications.

One of the most common applications of stamped sheet metal is in the automotive industry, where it is used for components such as chassis, body panels, and brackets. The lightweight nature of stamped parts contributes to improved fuel efficiency and better overall vehicle performance. Moreover, the current trend towards electric vehicles (EVs) further emphasizes the importance of stamped sheet metal, as manufacturers seek to reduce weight to maximize battery efficiency. In addition to automotive uses, stamped sheet metal finds applications in HVAC systems, appliances, and electronic enclosures, providing reliable solutions that meet stringent industry standards and performance requirements. By using advanced stamping techniques, companies can produce complex geometries while maintaining high precision, essential for the evolving demands of modern engineering innovations.

The stamped sheet metal market has been witnessing remarkable growth, driven by the increasing demand across various industries such as automotive, aerospace, and consumer electronics. Recent industry statistics indicate that the global market for stamped sheet metal products is projected to reach significant figures, with a compound annual growth rate (CAGR) that highlights a robust expansion in production capabilities and technological advancements. This growing trend emphasizes not only the rising utilization of stamped components but also the ongoing innovations aimed at improving efficiency and reducing costs in manufacturing processes.

Moreover, the versatility of stamped sheet metal applications is a key factor contributing to its market trends. Industries are embracing lightweight materials to enhance product performance and energy efficiency. In the automotive sector, for instance, there is a growing emphasis on the use of stamped components for vehicle bodies and interior structures, as manufacturers seek to reduce weight without compromising safety. This shift not only aligns with regulatory demands for lower emissions but also caters to consumer preferences for more fuel-efficient vehicles. As the landscape of manufacturing continues to evolve, stamped sheet metal remains pivotal in shaping the future of production across multiple sectors.