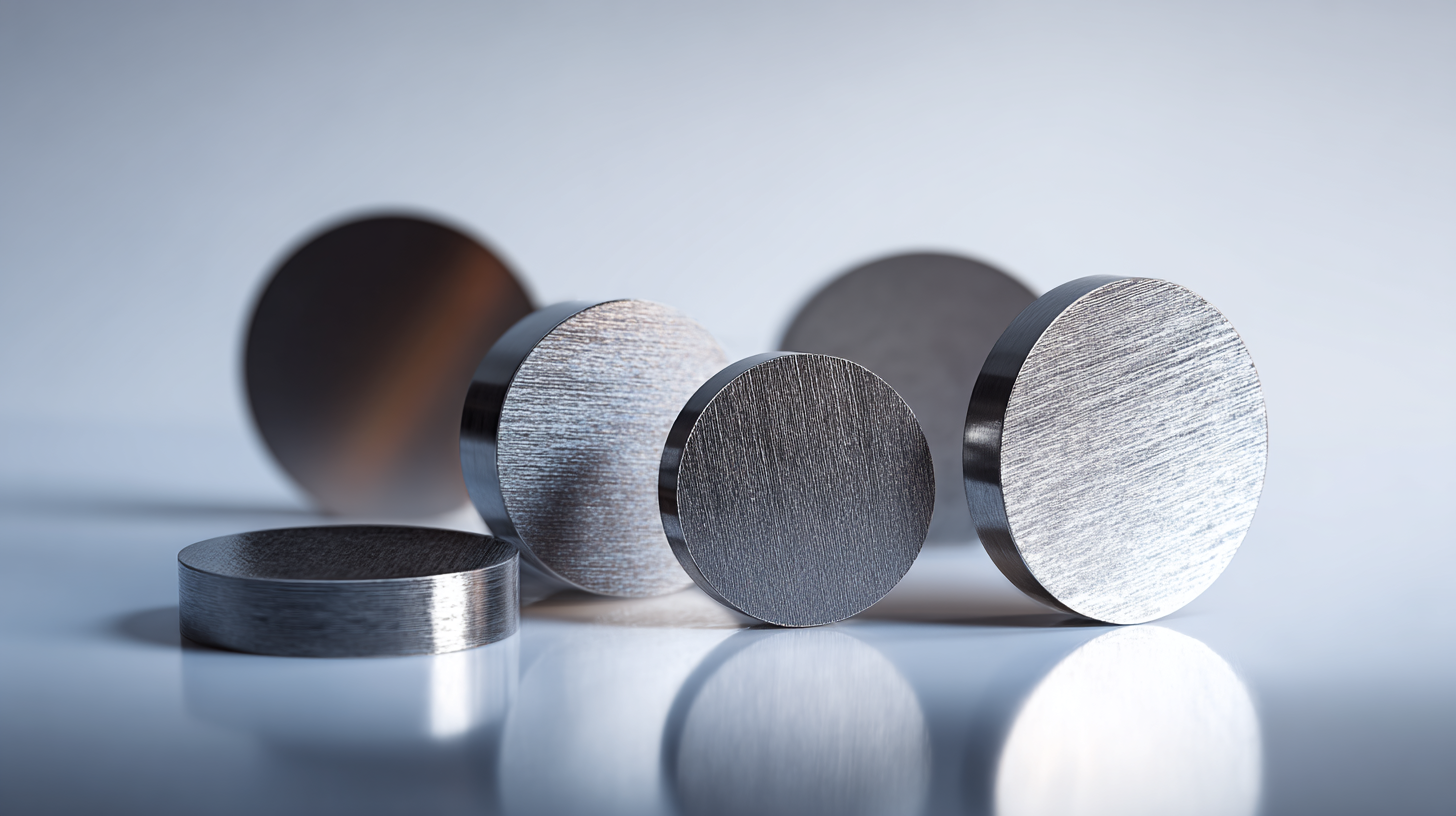

In our daily lives, we often encounter a seemingly simple object—the round metal disc. From kitchen tools and automotive components to advanced machinery, these discs play a crucial role in diverse applications, yet their significance often goes overlooked. Understanding the science behind round metal discs reveals a world of engineering precision, materials science, and innovative design. This article delves into the myriad ways these ubiquitous discs are manufactured, engineered, and utilized, shedding light on their structural integrity, functional versatility, and the fascinating principles that govern their performance. Whether you’re curious about the processes that make a durable cooking surface or interested in the dynamic roles these discs play in technology, we'll explore the essentials of round metal discs and how they continue to shape our environment and everyday experiences. Join us as we unfold the captivating story behind these extraordinary yet commonplace objects.

Round metal discs are ubiquitous in our daily lives, often overlooked yet vital to a multitude of applications. Their unique properties, such as strength, density, and conductivity, make them ideal for everything from household items to industrial machinery. For example, in appliances, these discs are commonly found in components like bearings and gears, where durability is essential for performance.

Tips: Consider using round metal discs in DIY projects for enhanced stability. Their robust nature can be leveraged to create sturdy bases for furniture or mounts for various objects. Additionally, when choosing metal discs, pay attention to their alloy composition; certain metals may provide better resistance to corrosion, making them perfect for outdoor or high-moisture environments.

In automotive applications, round metal discs serve critical functions as brake components and wheels. Their balanced shape contributes to smooth rotation and stability, ensuring safety on the road. Furthermore, their ability to withstand high temperatures and pressures is crucial in many mechanical systems. With innovative designs and materials, the future of round metal discs promises even more exciting applications, enhancing functionality in both existing and emerging technologies.

Round metal discs play a pivotal role in several key industries, transforming everyday applications and enhancing efficiency. In the automotive sector, these discs are fundamental in the production of brake pads and rotors. Their design ensures optimal performance and safety, providing the necessary friction and heat dissipation required during braking. The precision engineering behind these discs not only improves vehicle safety but also contributes to fuel efficiency by reducing drag and weight.

In the electronics industry, round metal discs are used in components such as capacitors and connectors. Their shape allows for compact designs while maintaining electrical efficiency and reliability. This is crucial for the development of smaller and more powerful devices, supporting the rapid innovation of smartphones, laptops, and other consumer electronics. Similarly, in the manufacturing sector, metal discs are integral in CNC machining and stamping processes, streamlining production and enhancing the quality of the outputs. Their versatility in design and application underscores the profound impact round metal discs have across diverse industries.

| Industry | Application | Material | Size (Diameter in mm) | Function |

|---|---|---|---|---|

| Automotive | Brake Discs | Cast Iron | 300 | Friction and braking |

| Electronics | Connectors | Copper | 15 | Electrical conductance |

| Manufacturing | Gaskets | Rubber | 100 | Sealing and insulation |

| Aerospace | Discs in turbines | Titanium | 250 | High temperature resistance |

| Medical | Surgical Discs | Stainless Steel | 20 | Precision cutting |

When selecting round metal discs for your project, there are several critical factors to consider to ensure functionality and efficiency. According to a report by the Metal Discs Industry Association, the demand for precision-engineered metal components has seen a 20% increase over the past five years, emphasizing the importance of making informed choices.

Tips for selecting the right round metal disc include assessing the material properties such as thickness, diameter, and alloy type, as these can significantly impact performance. For example, stainless steel discs are known for their corrosion resistance and durability, making them ideal for applications in harsh environments, while aluminum discs are lightweight and malleable, suitable for ease of manufacturing.

Additionally, always consider the disc's intended application. For high-temperature applications, a higher-grade metal with exceptional thermal resistance may be necessary. A 2022 industry survey revealed that 75% of engineers cite compatibility with existing systems as a top priority when choosing metal discs. Understanding these aspects will help you select a round metal disc that meets your project's specific demands effectively.

Round metal discs are at the forefront of innovation across various technology sectors, demonstrating their versatility and utility. In the automotive industry, these discs serve critical roles as brake rotors, ensuring efficient energy transfer and heat dissipation. Their ability to withstand high temperatures and provide consistent performance makes them indispensable for vehicle safety and efficiency. Additionally, advancements in materials science have led to the creation of lighter and stronger variants, further enhancing their application range.

In consumer electronics, round metal discs are prevalent in components such as speakers and hard drives. The precision engineering of these discs contributes significantly to sound quality and data storage efficiency. Magnets and other electromagnetic components often rely on these discs for optimal functionality, showcasing their importance in modern devices. Furthermore, the rise of smart technology has seen an increase in the use of round metal discs in sensors and wearables, where their compactness and durability allow for seamless integration into a variety of applications.

Round metal discs play a crucial role in enhancing the performance and efficiency of a wide range of products, from automotive components to electronic devices. According to a recent report by Grand View Research, the global market for metal components, including discs, is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2028. This uptick is largely driven by increasing demands for lightweight and durable materials in manufacturing, where round metal discs serve as vital elements in improving operational efficiency.

In automotive applications, for instance, round metal discs are integral in brake systems. A study by the Society of Automotive Engineers indicates that the adoption of advanced metal discs has led to a 15% reduction in stopping distance and a 20% increase in heat dissipation, significantly enhancing vehicle safety and performance. Beyond automotive uses, these discs are also essential in consumer electronics, where they help manage heat effectively, contributing to increased longevity and efficiency of devices. The optimization of thermal properties through the use of high-quality metal discs can improve electronic efficiency by up to 30%, emphasizing their importance in both everyday applications and industrial uses.

This chart illustrates the efficiency improvement percentages of various products that utilize round metal discs in their design. The data represents the enhancements in performance across selected applications.