In today’s competitive manufacturing landscape, choosing the right components can make all the difference in efficiency and product quality. Metal stamping discs have emerged as a vital element in many production processes, offering precision, durability, and cost-effectiveness. According to industry expert John Smith, a renowned metallurgical engineer, “The versatility and reliability of metal stamping discs can significantly enhance the performance of your manufacturing operations.”

The advantages of utilizing metal stamping discs extend beyond mere functionality. These discs are designed to meet specific tolerances and can be produced in a plethora of shapes and sizes, catering to diverse applications across various sectors. As industries continue to evolve and demand higher standards, the role of metal stamping discs becomes increasingly prominent. They not only streamline production but also contribute to the overall quality of the finished products, making them an indispensable choice for manufacturers looking to innovate and excel in their markets.

As we delve deeper into the reasons for selecting metal stamping discs for your manufacturing needs, we will explore their applications, benefits, and the technological advancements that have allowed them to stand out as a preferred solution in modern manufacturing practices.

Metal stamping discs have emerged as a vital component in various manufacturing processes due to their numerous benefits. One of the most significant advantages is their precision. According to a report by the Precision Metalforming Association (PMA), approximately 90% of manufacturing companies that utilize metal stamping techniques noted an improvement in part accuracy, resulting in less waste and higher production efficiency. The ability to produce highly intricate designs with minimal tolerances makes metal stamping discs an essential tool in industries ranging from automotive to aerospace, where part reliability is paramount.

Additionally, metal stamping discs contribute to cost-effectiveness in manufacturing. A study published in the Journal of Manufacturing Science and Engineering highlights that companies adopting metal stamping methods can reduce production costs by up to 40% compared to traditional machining techniques. This cost reduction is primarily attributed to the lower material waste and the speed of production, enabling manufacturers to meet tight deadlines without compromising quality. Furthermore, the use of durable materials in metal stamping ensures that the finished products exhibit longevity, reducing the need for frequent replacements or repairs, thus providing additional savings in the long term. As a result, manufacturers seeking to enhance both productivity and profitability are increasingly turning to metal stamping discs to meet their operational goals.

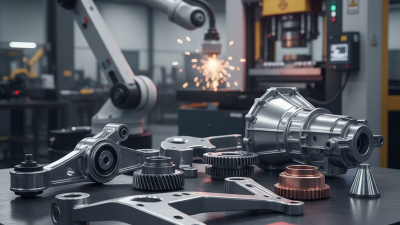

Metal stamping discs are versatile components widely used across various industries, contributing significantly to the efficiency and quality of manufacturing processes. In the automotive sector, for instance, these discs play a critical role in the production of precision parts such as brackets and housings. Manufacturers benefit from the ability to create intricate designs that meet stringent safety and performance standards, ensuring that their products can handle the demands of modern vehicles.

In the electronics industry, metal stamping discs are equally valued for their ability to produce high-precision components, such as contact points and housings for circuit boards. The consistent quality and adaptability of these discs allow for rapid prototyping and mass production, which are essential in keeping up with the fast-paced technology market. Additionally, the aerospace industry employs stamping discs for lightweight yet durable components, helping optimize fuel efficiency and performance in aircraft. As manufacturing needs continue to evolve, the applications of metal stamping discs will likely expand, showcasing their essential role across diverse sectors.

| Industry | Application | Material Used | Benefits |

|---|---|---|---|

| Automotive | Manufacturing components like brackets and plates | Stainless Steel, Aluminum | Durability, Corrosion resistance |

| Electronics | Production of components such as heat sinks and housings | Copper, Steel | Excellent conductivity, Precision |

| Aerospace | Creating components like brackets, spacers, and housings | Titanium, Aluminum | Lightweight, High strength |

| Medical | Production of surgical instruments and medical devices | Stainless Steel | Hygienic, Sterilizable |

| Construction | Manufacturing structural components | Steel, Metal Alloys | Strength, Longevity |

When selecting metal stamping discs for manufacturing needs, several key considerations should guide your decision-making process. First and foremost, material selection is crucial. Different projects may require discs made from various metals such as stainless steel, aluminum, or brass, depending on the application's specific requirements. Consider factors such as corrosion resistance, strength, weight, and thermal conductivity to ensure that the chosen material aligns well with your operational conditions and end-use performance.

Another important aspect is the tolerance and precision of the stamped discs. High-quality metal stamping should provide precise dimensions to ensure proper fit and function within the overall assembly. It is important to communicate the required tolerances to your manufacturer to ensure they possess the necessary equipment and capabilities to meet your specifications. Additionally, look into the manufacturer's experience and track record within your industry, as this can impact both the quality of the final product and turnaround times. By focusing on material choice and manufacturing precision, you can significantly enhance the performance and reliability of your metal stamping components.

When it comes to manufacturing components, the choice of materials can significantly impact both the production process and the final product's performance. Metal stamping discs have long been favored for their durability and precision. Compared to alternative materials such as plastic or composites, metal stamping offers superior strength and longevity. Metal discs hold their shape and structural integrity under various manufacturing conditions, making them ideal for heavy-duty applications where reliability is crucial.

In contrast, alternative materials often lack the strength-to-weight ratio that metal provides. While plastics can be lighter and less expensive initially, they may not withstand extreme temperatures or mechanical stresses as effectively as metal. Additionally, the long-term cost of plastic can increase due to potential replacements and maintenance needs. Composite materials, while versatile, often come with challenges related to manufacturing complexity and perform variably under different conditions. Thus, for applications requiring high performance and durability, metal stamping discs often emerge as the more reliable choice.

Quality control in the production of metal stamping discs is paramount to ensuring the reliability and performance of components used across various industries. According to a report by the International Organization for Standardization (ISO), adherence to strict manufacturing standards can lead to a reduction in defect rates by up to 60%. Implementing rigorous quality control measures and standards throughout the production process not only boosts the overall quality of the metal stamping discs but also enhances operational efficiency. This helps manufacturers minimize waste and reduce costs associated with rework and returns.

Moreover, certifications such as ISO 9001 play a critical role in standardizing quality control processes. This certification ensures that manufacturers consistently meet customer and regulatory requirements, which is crucial for sectors such as automotive and aerospace where component integrity is non-negotiable. The Metal Stamping Association highlights that companies engaged in stringent quality management practices can see an uptick in customer satisfaction by approximately 30%, contributing to long-term business success. Ensuring that metal stamping discs adhere to these quality standards is essential for manufacturers looking to maintain a competitive edge in the marketplace.