In the ever-evolving landscape of industrial applications, the demand for reliable sealing solutions remains paramount. Among these, steel gaskets stand out for their superior durability and performance in high-pressure environments. According to a recent market analysis by Grand View Research, the global gasket market is projected to reach $5.73 billion by 2025, with steel gaskets increasingly favored for their resilience against extreme temperatures and corrosive substances. This comprehensive tutorial aims to delve into the intricacies of mastering steel gaskets, highlighting their advantages, application methodologies, and the exploration of alternative gasket materials where necessary. As industries strive for enhanced efficiency and safety, understanding steel gaskets becomes not just advantageous, but essential for engineers and manufacturers seeking optimal performance in their operations.

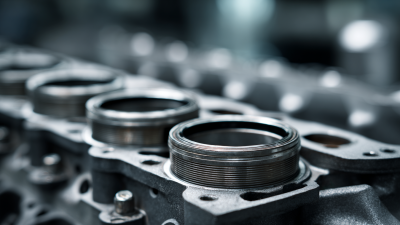

Steel gaskets are an essential component in many industrial applications, thanks to their robust properties and versatility. Understanding the different types and characteristics of steel gaskets is crucial for ensuring optimal performance in various environments. Commonly employed in industries such as automotive, aerospace, and manufacturing, steel gaskets are known for their durability, resistance to extreme temperatures, and ability to create effective seals in high-pressure situations.

Tips for selecting the right steel gasket include considering the operating conditions such as temperature, pressure, and the types of fluids involved. Always ensure that the gasket material is compatible with the media it will be exposed to, as this can significantly affect its longevity and reliability. Additionally, pay attention to the manufacturing standards and certifications of the gaskets to guarantee they meet industry requirements.

Furthermore, regular maintenance and inspection of steel gaskets can help prevent premature failure. Look out for signs of wear, leakage, or deformation, and replace gaskets as needed to maintain system integrity. By carefully choosing and maintaining steel gaskets, industries can enhance operational efficiency and minimize costly downtime.

When selecting the right steel gasket for industrial applications, several key considerations must be taken into account to ensure optimal performance and longevity. Firstly, understanding the operating conditions—such as temperature, pressure, and media compatibility—is crucial. According to a 2023 report by the International Society of Gasket Engineers (ISGE), over 60% of gasket failures in industrial settings can be attributed to improper selection based on these factors. For instance, high-temperature applications may necessitate the use of stainless steel gaskets that can withstand thermal expansion without compromising seal integrity.

Another important consideration is the gasket design and thickness. The ISGE also found that thickness variations can impact the sealing ability, with thicker gaskets providing better conformability to irregular surfaces but potentially increasing the risk of stress relaxation. Furthermore, material selection plays a vital role; carbon steel gaskets are often favored for their strength and resilience in a variety of environments, while alloyed steel options may be necessary for corrosive conditions. By prioritizing these factors, industry professionals can enhance the reliability and efficiency of their sealing solutions, ultimately reducing maintenance costs and downtime.

When it comes to the installation of steel gaskets, best practices are crucial for ensuring optimal performance in industrial applications. First and foremost, it is essential to prepare the mounting surfaces adequately. This involves cleaning the surfaces thoroughly to remove any dirt, debris, or old gasket material. A smooth and even surface will help achieve a proper seal, preventing leaks and enhancing the lifespan of the gasket. Utilizing a feeler gauge can assist in measuring the flatness of the surfaces, ensuring they meet the necessary specifications for effective installation.

Once the surfaces are prepared, the next step is to apply the correct torque settings during the installation. It is vital to follow the manufacturer's guidelines regarding torque values and sequence. A gradual, even tightening progression helps create a uniform compressive load on the gasket, which is key to maintaining its integrity under pressure. Additionally, utilizing a torque wrench can help in achieving the desired accuracy. Regularly verifying the torque settings throughout the operational life of the equipment can also prevent loosening and ensure continued efficiency in sealing applications.

Steel gaskets are essential components in various industrial applications, yet their implementation is often fraught with challenges. One common issue is improper sealing, which can lead to leaks and equipment failures. This often stems from incorrect installation techniques or inadequate surface preparation. To address these problems, it is crucial to ensure that mating surfaces are clean, smooth, and adequately deburred. Additionally, following the manufacturer's guidelines for torque specifications can help achieve the necessary compression for a reliable seal.

Another challenge that users frequently face is corrosion, particularly in aggressive environments. Steel gaskets may be susceptible to rust when exposed to moisture and harsh chemicals. To combat this, industries can opt for gaskets made from corrosion-resistant materials or apply protective coatings to the gasket surfaces. Furthermore, regular maintenance and inspections can help identify wear and tear before it leads to significant issues, thereby prolonging the lifespan of the gaskets and ensuring the overall integrity of the systems in which they are used.

Steel gaskets play a crucial role in ensuring the reliability and efficiency of industrial machinery. According to a recent report by the Association of Mechanical Engineers, improper maintenance of gaskets can lead to leaks, which account for up to 40% of downtime in plants. To enhance the longevity and reliability of steel gaskets, it is vital to adopt a proactive maintenance approach. Regular inspection for wear and tear, as well as monitoring operating temperatures and pressures within the specified limits, can significantly reduce the likelihood of gasket failure.

Steel gaskets play a crucial role in ensuring the reliability and efficiency of industrial machinery. According to a recent report by the Association of Mechanical Engineers, improper maintenance of gaskets can lead to leaks, which account for up to 40% of downtime in plants. To enhance the longevity and reliability of steel gaskets, it is vital to adopt a proactive maintenance approach. Regular inspection for wear and tear, as well as monitoring operating temperatures and pressures within the specified limits, can significantly reduce the likelihood of gasket failure.

Another key maintenance tip is to ensure proper installation techniques. A report from the International Gasket Manufacturers Association highlights that nearly 30% of gasket failures are due to installation errors. Edge loading, improper torque specifications, and contamination can compromise gasket integrity. Implementing best practices during installation, such as using torque wrenches to achieve the correct tightness and ensuring the mating surfaces are clean and flat, can extend the lifespan of steel gaskets. By focusing on these maintenance strategies, industries can minimize operational disruptions and enhance the performance of their equipment.