In the realm of mechanical applications, the significance of Lip Seal Dimensions cannot be overstated. These dimensions play a critical role in ensuring the effective sealing and optimal performance of various machinery and equipment. As industries increasingly rely on advanced technologies, understanding the intricate specifications of lip seals becomes essential for engineers and technicians alike. The right lip seal dimensions not only enhance the sealing capabilities but also extend the lifespan of components, reduce maintenance costs, and improve overall efficiency. This article delves into key tips and insights to aid in selecting and optimizing lip seal dimensions, ultimately empowering professionals to make informed decisions for their specific applications. By embracing these essential guidelines, organizations can achieve superior performance and reliability in their mechanical systems.

Selecting the right lip seal dimensions is crucial for ensuring optimal performance in various mechanical applications. The dimensions not only impact the seal's ability to prevent leaks but also influence the overall efficiency and longevity of mechanical components. Different environments and operating conditions present unique challenges, necessitating a careful evaluation of seal designs.

For instance, in applications exposed to harsh conditions, innovative designs with integral dirt exclusion lips and robust protection features can significantly enhance reliability.

In addition, understanding the specific requirements for different mechanical systems, such as pumps and hydraulic cylinders, is essential. The reliability of mechanical seals can be estimated using advanced analytical techniques, taking into account factors like model uncertainty.

As industries evolve, particularly in sectors such as oil and gas and hybrid-electric technologies, the demand for precision sealing solutions continues to grow.

By aligning seal dimensions with application needs, manufacturers can improve performance and reduce maintenance costs, ultimately leading to greater operational efficiency.

In mechanical applications, the performance of lip seals is significantly influenced by the properties of the materials used in their construction. According to a report by the Society of Tribologists and Lubrication Engineers (STLE), the choice of elastomer compounds can affect wear resistance and temperature tolerance, which are critical for maintaining seal integrity under operational stresses. For instance, Nitrile rubber, a common choice, exhibits excellent resistance to petroleum-based oils and fuels, but its performance may drop in high-temperature applications, highlighting the need for careful material selection based on operational conditions.

Furthermore, the material's hardness plays a pivotal role in the sealing capability of lip seals. A study published in the Journal of Mechanical Engineering Testing indicates that seals made from softer materials generally provide better conformability, allowing for improved sealing against surface irregularities. However, they may wear more quickly under high pressure or abrasive conditions. As seal manufacturers innovate with new composite materials and advanced polymer formulations, understanding these material properties becomes essential for engineers seeking optimal performance in their mechanical systems. This knowledge ensures that the selected lip seal not only fits the dimensional requirements but also adequately withstands the specific operational challenges it will face.

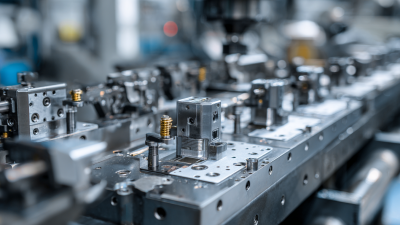

The efficiency of mechanical applications heavily relies on understanding the dimensions of lip seals. Proper lip seal width and diameter are crucial when it comes to optimizing sealing performance and minimizing frictional losses. Recent studies have highlighted the importance of accurately calculating these dimensions to achieve maximum efficiency in various industrial settings. For instance, a numerical simulation evaluating the sealing performance and hydrodynamic lubrication models has shown that maintaining full film lubrication significantly enhances the lifespan of rotary lip seals, indicating that precise dimensions can lead to superior operational outcomes.

When installing lip seals in mechanical applications, avoiding common mistakes is crucial for ensuring their

optimal functionality. One prevalent error is inadequate surface preparation. Before installation, the mating surfaces should be cleaned

and inspected for any imperfections. Contaminants such as dust, oil, or grease can

hinder the seal’s performance and lead to premature failure. Additionally, ensuring that the surfaces are free of sharp edges or burrs is essential,

as these can cause damage to the seal during installation, compromising its integrity.

Another common mistake is incorrect alignment during installation. Lip seals depend on precise positioning;

misalignment can cause uneven wear and lead to leaks. It’s vital to use proper tools and techniques to align the seal with the shaft or housing correctly.

Over-torquing the seal or forcing it into place can also adversely affect its performance. Proper installation

techniques, such as utilizing a seal installation tool or following manufacturer guidelines, can help

avoid these pitfalls and ensure that the lip seal functions effectively throughout its intended lifespan.

Lip seals are crucial components in mechanical systems, providing essential functions such as preventing leakage and retaining lubricants. To ensure their longevity and optimal performance, regular maintenance is vital. Proper care can significantly extend the life of lip seals, reducing downtime and replacement costs in mechanical applications.

One important tip is to regularly inspect the seals for signs of wear or damage. Look for cracks, tears, or deformation in the material, as these can compromise the seal's effectiveness. Additionally, maintaining the correct operating temperature and pressure within the system can minimize stress on the seals, promoting their durability.

Another key maintenance tip is to ensure that the sealing surface is clean and smooth. Contaminants can cause premature wear, so it’s advisable to clean the surfaces and check for any sharp edges or particulate matter that could harm the seal. Using compatible lubricants can also help reduce friction and provide a protective layer, ultimately enhancing the performance and lifespan of lip seals in your mechanical systems.