When embarking on a new engineering project, one of the critical components that can significantly affect the success and longevity of your assembly is the steel gasket. Understanding how to select the right steel gasket involves more than just picking a random piece; it requires careful consideration of various factors such as material properties, application requirements, and environmental conditions. In this blog post, we will explore seven essential tips that will guide you through the process of choosing the most suitable steel gasket for your specific needs. From understanding the different types and designs to assessing the specifications that match your project demands, these insights will ensure optimal performance and reliability of your equipment. Whether you are an experienced engineer or a newcomer to gasket selection, this guide will equip you with the knowledge necessary to make an informed decision and enhance the effectiveness of your project.

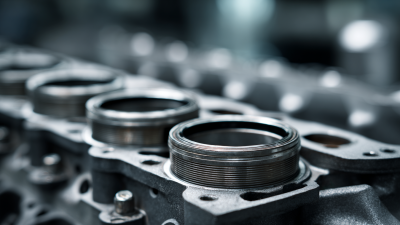

When selecting the right steel gasket for your project, it's essential to understand the different types available and their specific applications. Steel gaskets come with varying designs and materials that cater to distinct sealing needs. For instance, multi-layer steel (MLS) gaskets are engineered for high-performance applications, including modern combustion engines. They provide superior sealing under extreme conditions, ensuring that combustion pressures stay contained while facilitating coolant flow.

When selecting the right steel gasket for your project, it's essential to understand the different types available and their specific applications. Steel gaskets come with varying designs and materials that cater to distinct sealing needs. For instance, multi-layer steel (MLS) gaskets are engineered for high-performance applications, including modern combustion engines. They provide superior sealing under extreme conditions, ensuring that combustion pressures stay contained while facilitating coolant flow.

One crucial tip when choosing a steel gasket is to recognize the importance of installation. Many manufacturers advise against using sealants with certain steel gaskets, especially MLS types. These gaskets are designed to be installed dry, and applying additional substances can compromise their effectiveness. Additionally, consider the operating environment; some gaskets perform better under certain pressures and temperatures than others, making it essential to match the gasket type with the specific requirements of your project.

Finally, it's vital to stay updated about advancements in gasket technology. As manufacturers innovate to meet modern demands, familiarizing yourself with the latest designs and materials will help you make informed choices. Whether you're dealing with heavy oil applications or high-performance engines, understanding the properties and suitable uses of different steel gaskets is key to ensuring long-lasting and reliable seals.

When selecting steel gaskets for optimal performance, several key factors must be considered to ensure that the chosen gasket adequately meets the demands of your project. Material compatibility is paramount; gaskets must withstand the specific chemicals and temperatures present in the application to prevent failure. According to a recent industry report, approximately 30% of gasket failures are attributed to improper material selection, emphasizing the importance of choosing the right alloy based on the environmental factors at play.

Another critical aspect is the gasket’s thickness and design. Thicker gaskets often provide better sealing but may require more clamping force, which can lead to deformation if not managed correctly. It's recommended to consult technical specifications and manufacturer data, as studies reveal that up to 25% of leakage incidents stem from inappropriate gasket dimensions. Always ensure that the gasket design aligns with the flange configuration and pressure requirements of your specific application.

Lastly, consider the installation process and maintenance needs. Gaskets require appropriate installation techniques to prevent issues such as point loading and uneven compression. Industry standards suggest following best practices for installation, as up to 50% of gasket-related leaks can be traced back to improper installation techniques. Investing time in understanding these essential factors can significantly enhance the performance and longevity of your steel gaskets.

When selecting a steel gasket for your project, it is crucial to assess the compatibility of the gasket material with the other components in your system. Steel gaskets are often subjected to extreme conditions, including high temperatures and pressures, that can lead to material degradation if compatibility is overlooked. According to a report by the Gasket and Sealing Association, improper material selection can lead to a failure rate of up to 30% in industrial applications. Therefore, evaluating the chemical and physical properties of both the gasket and the mating surfaces is vital to ensure longevity and effectiveness.

Conducting a material compatibility analysis involves examining factors such as corrosion resistance and temperature tolerance. The ASTM G31 standard provides guidelines for evaluating the corrosive attack of various environments on metals, which can serve as a useful reference for determining the suitability of a steel gasket in specific applications. Furthermore, data compiled by the International Society of Automation indicates that mismatched materials can not only lead to leaks and failures but also result in significant financial losses, sometimes exceeding $1 million in industries like oil and gas. Aligning gasket materials with project requirements is essential for maintaining operational integrity and minimizing risks.

| Tip Number | Tip Description | Material Compatibility | Temperature Resistance (°C) | Pressure Rating (MPa) |

|---|---|---|---|---|

| 1 | Identify Project Requirements | Steel, Aluminum | -30 to 120 | 10 |

| 2 | Consider Chemical Resistance | Corrosive Fluids | -20 to 150 | 12 |

| 3 | Select the Right Thickness | Alloy Steels | -40 to 200 | 15 |

| 4 | Check Surface Finish | Rough Surfaces | -10 to 180 | 8 |

| 5 | Evaluate Load and Stress | High-Pressure Systems | -50 to 250 | 20 |

| 6 | Review Installation Guidelines | All Gasket Types | -30 to 130 | 10 |

| 7 | Consult with a Specialist | Varies by Application | -40 to 300 | 25 |

When selecting steel gaskets for your project, avoiding common pitfalls is crucial for ensuring durability and performance. One frequent misstep is neglecting to consider the specific application requirements. Different environments, such as gas versus diesel, can dramatically impact gasket performance. According to industry reports, approximately 30% of gasket failures in demanding applications stem from improper material selection. Therefore, ensure you assess temperature ranges and chemical compatibility before making a purchase.

When selecting steel gaskets for your project, avoiding common pitfalls is crucial for ensuring durability and performance. One frequent misstep is neglecting to consider the specific application requirements. Different environments, such as gas versus diesel, can dramatically impact gasket performance. According to industry reports, approximately 30% of gasket failures in demanding applications stem from improper material selection. Therefore, ensure you assess temperature ranges and chemical compatibility before making a purchase.

Another mistake often made is disregarding the installation process. A well-designed gasket can fail if not installed correctly. It's essential to follow proper torque specifications and sequence to avoid uneven pressure distribution. As highlighted in recent studies, over-tightening can lead to gasket deformation, while under-tightening might result in leaks, both of which compromise the integrity of your engine.

Lastly, many overlook the importance of manufacturer reputation and product reviews. Leveraging insights from industry experts and user experiences can guide you to more reliable options. Research shows that using established brands can reduce the likelihood of gasket failure by up to 25%, providing additional peace of mind for your projects.

When it comes to the installation and maintenance of steel gaskets, adherence to best practices is crucial for ensuring the integrity and longevity of your projects. According to a report by the Engineering Equipment and Materials Users Association (EEMUA), incorrect installation is responsible for nearly 60% of gasket-related failures. This underscores the importance of meticulous surface preparation, alignment, and torque application during the installation process. Utilizing proper torque specifications, often derived from the manufacturer’s guidance, can minimize the risk of leakage and enhance gasket performance significantly.

In the realm of maintenance, regular inspections play a pivotal role in the lifecycle of steel gaskets. A study from the American Society of Mechanical Engineers (ASME) indicated that consistent monitoring can lead to a 30% reduction in unplanned downtime due to gasket failures. It is essential to look for signs of wear, such as distortion or leakage, and to replace gaskets as necessary, following the recommended service intervals. Implementing a robust maintenance schedule not only ensures the optimal functioning of gaskets but also contributes to overall operational efficiency and safety within industrial settings.

This bar chart illustrates the importance of various factors when choosing steel gaskets, based on a survey assessing their significance for projects.