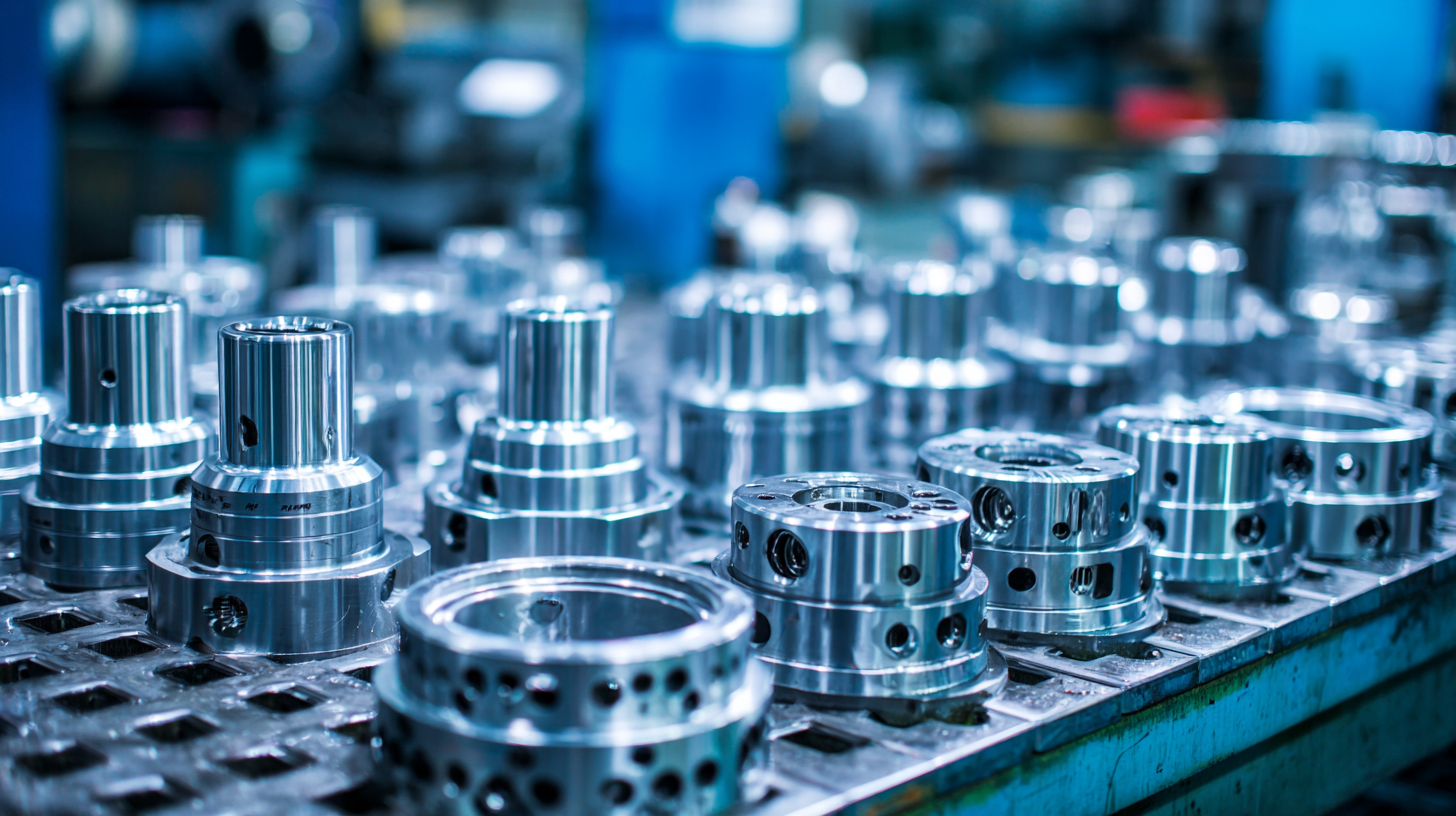

When it comes to manufacturing processes, selecting the right components is crucial for achieving both quality and functionality, especially in industries that rely on precision engineering. Stainless steel stamped parts have gained immense popularity due to their versatility, durability, and resistance to corrosion. However, choosing the best stainless steel stamped parts can be a daunting task, as there are various factors to consider to ensure that you meet your project's specific needs. Whether you are facing challenges with material selection, part design, or production methods, understanding the essential elements of stainless steel stamped parts is imperative. In this blog, we will explore seven essential tips that will guide you through the decision-making process, helping you avoid common pitfalls and select the optimal parts for your applications.

Understanding stainless steel is crucial when it comes to choosing the best stamped parts for your projects. Stainless steel is an alloy primarily made of iron, with chromium content that is typically greater than 10.5%. This chromium provides corrosion resistance, making stainless steel a preferred material in various industries such as automotive, aerospace, and medical devices. According to a report by the International Stainless Steel Forum (ISSF), global stainless steel production reached approximately 50 million metric tons in 2021, highlighting its significant role in modern manufacturing.

When selecting the best stainless steel stamped parts, it is essential to consider key factors in the stamping process. The global metal forming tools market is projected to grow from $29.41 billion in 2025 to an impressive $51.67 billion by 2032, indicating a robust CAGR of 8.4%. This growth underscores the importance of adopting advanced in-process monitoring strategies to ensure precision during stamping. Evaluating aspects like force, geometry, and temperature can lead to enhanced quality and reduced waste.

One crucial tip involves leveraging emerging trends in the metal stamping market, particularly advancements in CNC and automation technologies. These innovations are vital, especially in high-demand sectors like automotive and aerospace. Businesses should also focus on understanding the deformation mechanics involved in forming processes, as this knowledge can significantly impact the quality of the final product. Inherent uncertainties within the stamping process can be addressed through optimization techniques, ensuring that companies remain competitive in this evolving market landscape.

When selecting stainless steel stamped parts, quality control measures are critical to ensuring the integrity and durability of the final product. According to a report by the International Organization for Standardization (ISO), organizations with rigorous quality management systems see a 30% reduction in defect rates. Implementing thorough inspections at various stages of production, from raw material selection to final output, can significantly enhance product reliability.

In addition, adhering to standards such as ASTM A240 for stainless steel specifications can further support quality control. Data from the American Society for Testing and Materials indicates that components manufactured under such specifications exhibit 25% greater resistance to corrosion, which is crucial for industries like automotive and aerospace where component longevity is paramount. Therefore, implementing consistent quality checks and adhering to established standards not only mitigates risk but also fosters customer confidence in the durability of stainless steel parts.

When considering the selection of stainless steel stamped parts, the role of material sourcing cannot be overlooked. High-quality components stem not just from superior design, but from the careful choice of materials used in their production. With an increasing emphasis on sustainability, sources of materials are shifting significantly. Companies are recognizing the benefits of sourcing from renewable resources, such as natural fibers and eco-friendly composites, which can enhance the overall integrity and durability of stamped parts while also reducing environmental impact.

Innovative material sourcing strategies, much like the creative approaches adopted by African businesses in repair and repurposing, serve as a guide for optimizing production processes. By focusing on recycled or repurposed materials alongside traditional metals, manufacturers can create a more resilient supply chain. Moreover, embracing eco-friendly alternatives, such as hybrid materials, can lead to the development of more sustainable and durable components in industries ranging from automotive to consumer goods. This shift not only improves product longevity but also aligns with a growing demand for ethical manufacturing practices.

When selecting stainless steel stamped parts, the reputation of the supplier plays a crucial role in ensuring quality and reliability. According to a recent study by the Precision Metalforming Association, 75% of manufacturers consider supplier reputation as a top factor in their purchasing decisions. A reputable supplier is more likely to adhere to industry standards and provide parts that meet predetermined specifications, reducing the risk of costly production delays due to subpar components.

When selecting stainless steel stamped parts, the reputation of the supplier plays a crucial role in ensuring quality and reliability. According to a recent study by the Precision Metalforming Association, 75% of manufacturers consider supplier reputation as a top factor in their purchasing decisions. A reputable supplier is more likely to adhere to industry standards and provide parts that meet predetermined specifications, reducing the risk of costly production delays due to subpar components.

Moreover, quality certification is another indicator of a supplier’s reliability. A survey conducted by the International Organization for Standardization (ISO) found that companies with ISO 9001 certification are 50% less likely to experience product defects. This highlights the importance of working with suppliers who have established quality management systems. By prioritizing suppliers with a strong reputation and proven track record, businesses can enhance their manufacturing processes and ensure the structural integrity of their stainless steel parts.