In the world of engineering, determining Lip Seal Dimensions is crucial for product longevity and performance. An accurate measurement ensures a proper fit, preventing leaks and mechanical failures. Manufacturers must consider various factors that influence the dimensions, such as material properties and application environments.

When we think about Lip Seal Dimensions, we often overlook the small details. A slight miscalculation can lead to significant issues. It’s essential to engage in thorough analyses and measurements. The right seal can enhance efficiency and extend the life of machinery.

However, mistakes happen. Errors in dimensioning can lead to waste and reduced reliability. Reflecting on past experiences helps refine the process of obtaining correct measurements. Lip Seal Dimensions should never be taken lightly; they carry heavy implications for functionality and safety in engineering applications.

When it comes to mechanical design, lip seal dimensions play a crucial role. These seals prevent leaks and protect internal components from contaminants. Proper dimensioning ensures seals fit correctly and maintain their effectiveness under pressure. A well-designed seal can increase the lifespan of machinery.

Understanding how to measure lip seals accurately can be tricky. Many designers overlook the importance of the seal's groove specifications. If the groove is too tight, it can lead to premature wear. Conversely, a loose fit may cause leakage. Therefore, taking precise measurements is essential.

Material choices also influence seal performance. Different materials respond uniquely to temperature and pressure variations. Designers often grapple with balancing durability and flexibility. Consider the environment the seal will operate in. Reflecting on these aspects helps improve design accuracy. Each decision impacts the overall function and reliability of the assembly.

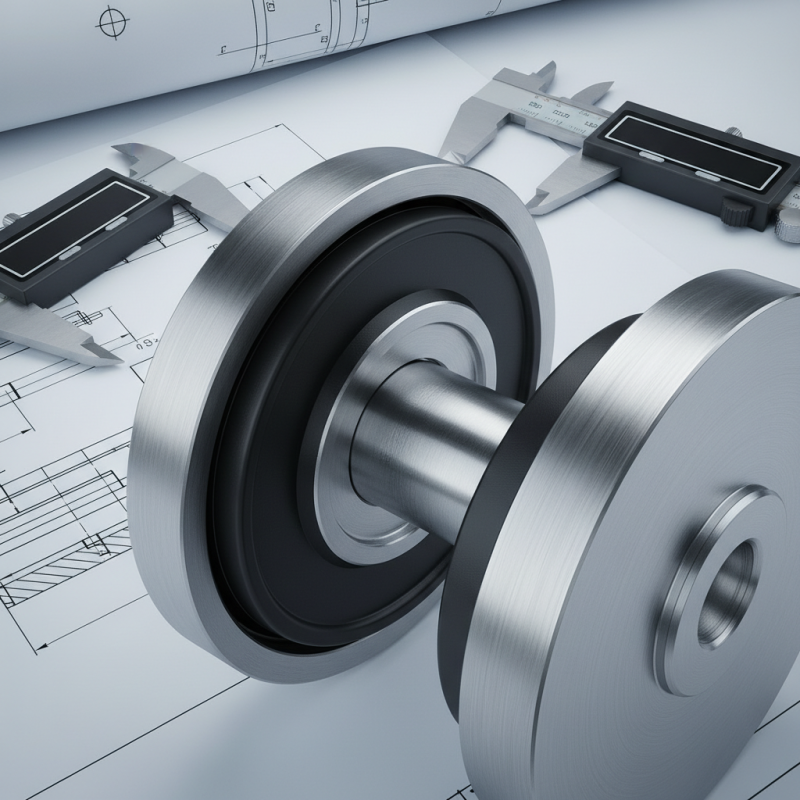

When determining lip seal sizes, several key factors come into play. The application environment influences the necessary dimensions. Temperature, pressure, and materials affect how seals perform. Reports show that improper sizing can lead to a failure rate of up to 25%. It’s crucial to assess these conditions carefully.

Another significant aspect is the material compatibility. Seals made from rubber, PTFE, or silicone each behave differently under specific conditions. Choosing the wrong material can result in premature wear. A study indicated that around 30% of industrial seal failures stem from material mismatch. This underlines the necessity for thorough research during the selection process.

**Tips:** Pay close attention to the expected operating conditions. A small oversight could lead to costlier repairs. Consider testing seals under real-world conditions before large-scale implementation. This can help identify potential problems early on. Regular maintenance and inspection can also contribute to extending the lifespan of the lip seals.

When measuring lip seal dimensions, accuracy is essential. Start by gathering the necessary tools. A caliper, a ruler, and a measuring tape will work well. Ensure all tools are in good condition. Dirty or damaged measuring tools can lead to incorrect dimensions.

Begin with the outer diameter. Place the caliper on the lip seal's edge. Make sure to read the measurement at eye level for precision. Then, measure the inner diameter. This step is crucial as it affects the seal's fit. If the lip seal is worn or damaged, the inner diameter may change. Check this carefully.

Next, measure the width of the lip. It's often overlooked but very important. A precise width ensures proper sealing. Use a ruler to avoid mistakes. Remember, even small errors in measurement can lead to problems. Evaluate your measurements after each step. If something feels off, take a moment to verify your results. Accurate measurements can prevent costly errors later on.

When determining lip seal sizes, many make common mistakes. One frequent error is neglecting to measure the shaft accurately. A miscalculation here can lead to improper sealing and leaks. Use calipers to get an exact measurement. Ensure the shaft's surface is clean and free of debris, as this can affect the fit.

Another mistake is overlooking material compatibility. Different environments require different materials. Using the wrong type can cause premature wear. For example, oil-resistant seals work well in oily conditions but may fail in water. Additionally, some overlook the importance of lip angle. The wrong angle can affect seal performance.

Lastly, don’t forget to account for the operating temperature and pressure during selection. Many people focus solely on size. That can lead to disaster. Balancing these factors ensures long-lasting performance. Careful attention to detail is essential when selecting lip seals. Each step matters significantly.

Determining the correct dimensions for lip seals is crucial for their performance and longevity. Proper fit ensures optimal sealing and reduces the risk of leaks. According to a report by the International Seal Manufacturers Association, nearly 30% of seal failures are related to improper dimensions. This highlights the importance of precise measurements during the design phase.

One factor to consider is the sealing lip's angle. A typical lip angle ranges between 5 to 20 degrees. An angle that is too steep can lead to premature wear. Conversely, a shallow angle might not provide adequate sealing force. Engineers must evaluate these angles based on application needs. In addition, stress analysis can be a helpful tool for predicting potential points of failure.

Temperature also plays a significant role in seal performance. Seals that operate beyond their temperature limits can fail, damaging the entire assembly. A study from the Society of Automotive Engineers indicates that heat resistance is critical in 70% of automotive applications. Yet, many designers overlook the potential impact of temperature fluctuations. Addressing these factors during the design process can significantly enhance the performance and lifespan of lip seals.