Choosing the right Metal Stamping Disc for your project can be challenging. With various sizes, shapes, and materials available, your selection greatly impacts the final outcome. Consider the specific needs of your project. Each project demands distinct qualities, and not all discs will suit your requirements.

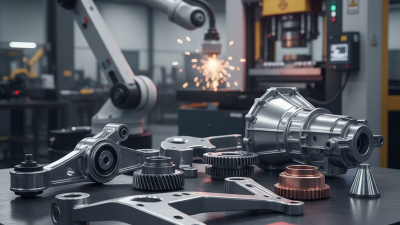

A Metal Stamping Disc can serve numerous applications, from automotive parts to electronics. Think about factors like thickness, diameter, and the type of metal used. These details influence durability and performance. Two identical discs may look the same but can behave differently under stress. It’s essential to choose wisely, as the wrong disc can lead to unexpected failures.

Take a moment to reflect on your previous experiences. Did you face issues with flexibility or strength? Analyzing past projects helps improve future choices. Remember, perfection is rarely achievable in every selection. However, making informed decisions and learning from mistakes can lead to better results. Always weigh the options carefully when selecting a Metal Stamping Disc.

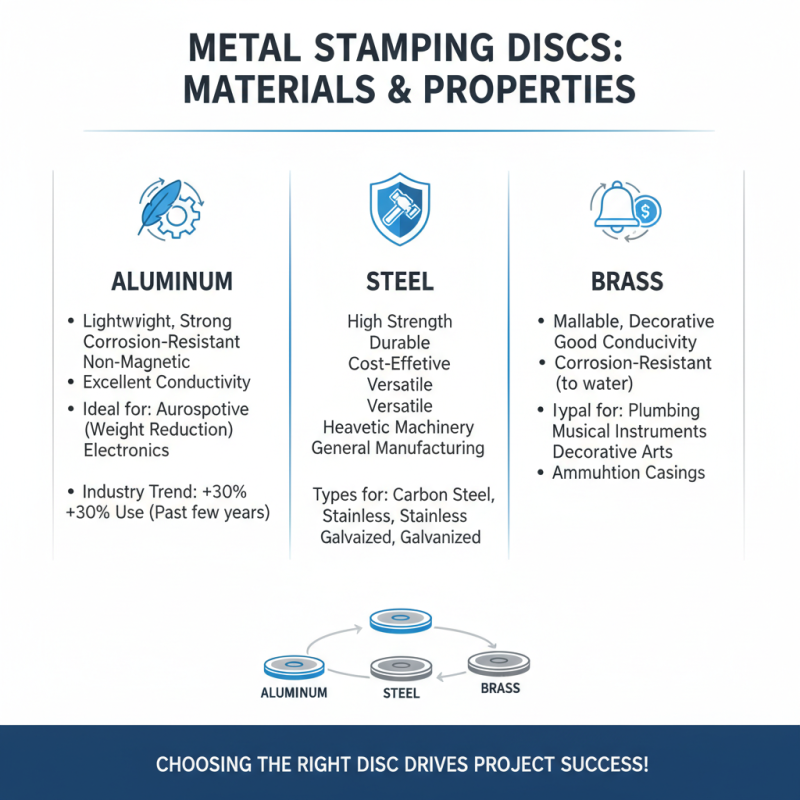

Metal stamping discs come in various types and materials. Understanding these options is essential for any project. Generally, discs are made from steel, aluminum, or brass. Each material has unique properties that affect performance. For example, aluminum is lightweight yet strong. It’s ideal for applications where weight matters. According to industry reports, aluminum's use in manufacturing has increased by over 30% in recent years.

Steel discs offer durability. They resist wear and can withstand high pressures. Projects that involve heavy machinery often require steel. In some cases, brass is preferred for its corrosion resistance. It provides excellent electrical conductivity, making it suitable for electrical components.

Choosing the right disc can be challenging. Many factors need consideration: thickness, hardness, and finish. A material too thin may fail under stress. Conversely, a very thick material might be unnecessary. As per recent surveys, 60% of manufacturers reported issues related to material selection. They experienced delays or operational issues during production. This highlights the importance of careful material assessment before making a decision. Each project is unique, and material choices should reflect that.

When selecting a metal stamping disc for your project, size, thickness, and shape are critical factors. Understanding specific requirements helps in making the right choice. According to the Fabricators & Manufacturers Association, 55% of projects require custom shapes. This means designers must focus on precision in dimensions. A custom shape can enhance functionality significantly, yet it complicates the production process.

Thickness is equally important. A report from the Metalforming Industry Association highlights that 40% of failures in metal stamping arise from incorrect thickness choices. Thin discs can bend or warp under pressure. Conversely, overly thick discs may increase weight and cost unnecessarily. Consider the application carefully. Is flexibility or strength your priority?

Size considerations should include both the diameter and the use-case. Larger discs may cause difficulties in stamping accuracy. Smaller discs may not provide enough material strength. Industry standards suggest consulting engineers or experienced fabricators during this phase. Each decision might lead to unexpected challenges later. Evaluating your specifications thoroughly is essential for success, yet many overlook this crucial step.

This chart illustrates key criteria for selecting the right metal stamping disc based on project requirements, including size, thickness, and shape complexity.

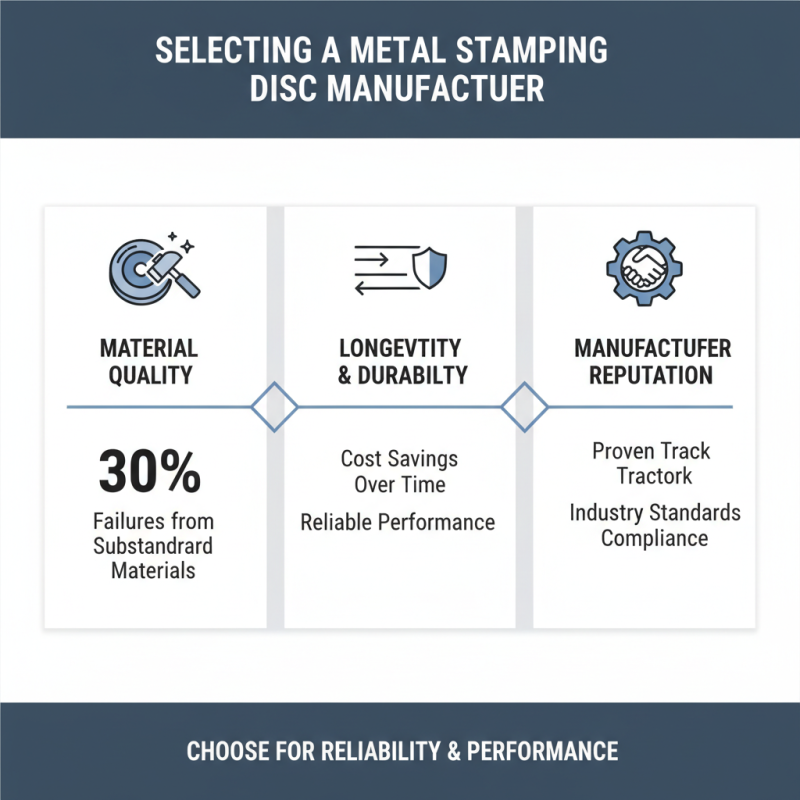

When selecting a metal stamping disc, quality is paramount. According to industry reports, over 30% of failed projects stem from poor-quality materials. Look for discs made from high-grade metals. Stainless steel and aluminum are common choices. These materials resist wear and corrosion, extending the lifespan of your tooling. Examine the manufacturing process, as precision engineering often correlates with disc quality. Discs produced using CNC technology usually provide tight tolerances, resulting in better performance.

Durability is another key feature. A robust stamping disc can withstand repetitive stress without deforming. Many industrial standards recommend checking the tensile strength of the material. For instance, a tensile strength of at least 400 MPa is advisable for most applications. Furthermore, surface finish can affect the disc's functionality. A smooth finish helps reduce friction during operation, leading to cleaner cuts and less temperature buildup. However, achieving the perfect finish can be challenging, and some may overlook this detail, leading to increased wear on the tools.

Lastly, consider the disc's thickness. Reports indicate that thicker discs often provide greater strength. However, this can also lead to more weight, which can affect machine performance. Balancing thickness with weight and strength is essential. Many users find themselves unsure about this aspect, creating room for trial and error in their projects. Prioritizing these quality features will enhance the success of your metal stamping endeavors.

When selecting a manufacturer for metal stamping discs, several factors experience significant weight. The quality of materials they use can directly impact the performance of your project. According to industry reports, over 30% of failures in metal components stem from substandard materials. Longevity is crucial; choosing a manufacturer who prioritizes quality can save costs in the long run.

Tip: Research manufacturers' certifications. Look for ISO or equivalent credentials. These can indicate quality assurance practices.

Experience also matters. A manufacturer with a solid track record will likely have refined processes. They understand common pitfalls and ways to avoid them. In a survey, 40% of companies noted that their biggest challenge was finding reliable suppliers. It's a critical consideration; the right partner can enhance your project's success.

Tip: Ask for samples. This simple step can provide insight into their manufacturing capabilities and attention to detail.

Cost shouldn't be the only factor. Some manufacturers offer low prices but lack quality solutions. Balancing affordability and quality is key. Evaluate past client testimonials for insights into reliability and performance. This can paint a clearer picture than just numbers.

When selecting metal stamping discs, cost and quality often collide. According to a report by the Metal Stamping Association, approximately 45% of projects overspend due to poor material choices. It's crucial to find a balance. High-quality metal discs usually provide superior durability. They perform better under stress and reduce the risk of defects in production.

Yet quality often comes with a premium price tag. For example, high-grade steel discs can cost upwards of 20% more than standard options. This can strain tight budgets. In fact, organizations that prioritize cost savings sometimes sacrifice quality. This leads to higher long-term expenses from increased rework and downtime.

Consider the lifespan of the product. Investing in quality can yield better results across time. A metal stamping disc with a lifespan of 10,000 cycles may seem costly initially. However, it saves money by minimizing replacements. Reflect on your project's needs. Is the lowest price really the best option? Sometimes, a cost-effective choice today can become a costly mistake tomorrow.

| Disc Material | Thickness (mm) | Diameter (mm) | Price per Unit ($) | Quality Rating (1-5) |

|---|---|---|---|---|

| Stainless Steel | 1.5 | 50 | 0.75 | 5 |

| Aluminum | 2.0 | 100 | 0.50 | 4 |

| Copper | 1.0 | 75 | 1.00 | 4.5 |

| Carbon Steel | 2.5 | 80 | 0.65 | 3.5 |

| Plastic Coated | 1.2 | 60 | 0.40 | 3 |