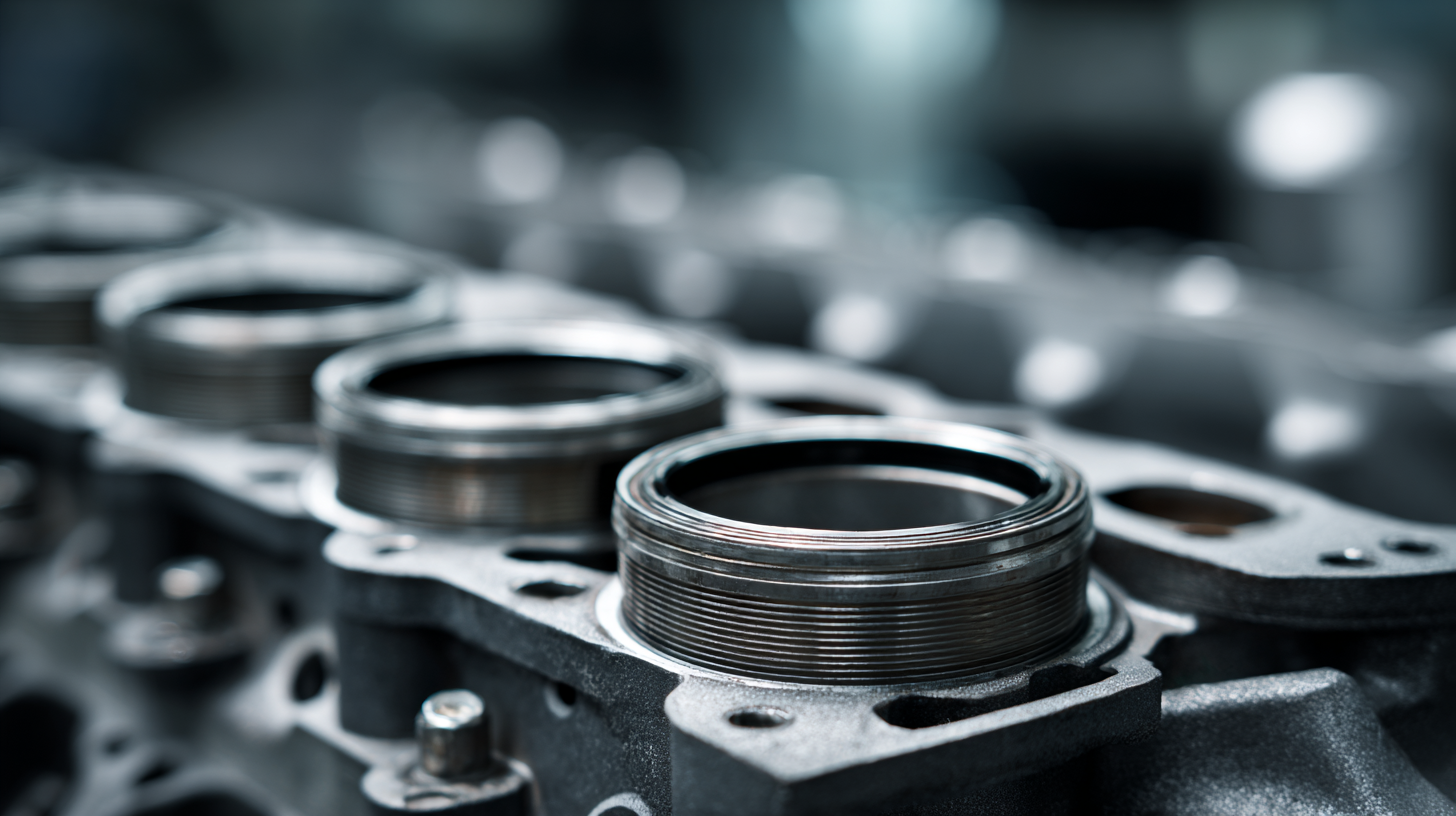

Automotive gaskets play a crucial role in ensuring the optimal performance of an engine, acting as seals that prevent leaks and maintain pressure within various components. According to a report by MarketsandMarkets, the global automotive gasket market is projected to reach USD 5.79 billion by 2025, driven by the increasing demand for high-performance vehicles and advancements in automotive technologies. The selection of the right automotive gasket is vital not only for maintaining engine efficiency but also for enhancing durability and reducing emissions. With the complexity of today's engines, which often feature a combination of metals and composite materials, the need for appropriate gasket types tailored to specific engine designs cannot be overstated. As manufacturers continue to innovate, understanding the different types of gaskets available and their specific applications becomes essential for both performance tuning and ensuring long-term reliability.

Gaskets play a crucial role in the overall performance and longevity of an engine. Their primary function is to create a seal between different engine components, preventing leaks of fluids and gases. A well-designed gasket can reduce contamination caused by external pollutants, which is critical given the variety of contaminants commonly found in used engine oil. These contaminants can lead to significant wear and tear on engine components, potentially shortening the engine's lifespan.

Recent trends in gasket development reflect the growing demands of high-performance engines. As engine power levels rise and component diversity increases, manufacturers are focusing on creating gaskets that can withstand higher pressures and temperatures. This innovation is vital, especially when servicing expectations are evolving. For instance, a report indicates that the exhaust flange gasket market is projected to grow substantially, from USD 2.5 billion in 2024 to USD 3.8 billion by 2033, highlighting the increasing reliance on advanced gasket technologies in the automotive sector. Ensuring that leak prevention begins at the assembly stage can mitigate potential performance issues, reinforcing the need for quality gaskets tailored to specific engine requirements.

When it comes to automotive engines, choosing the right gaskets is crucial for maintaining optimal performance. There are several types of automotive gaskets, each designed for specific applications. For instance, cylinder head gaskets are essential for sealing the combustion chamber and preventing coolant and oil leaks, which can lead to engine overheating. According to a report from the Automotive Aftermarket Suppliers Association, improper gasket selection can account for nearly 15% of engine failures, underscoring the importance of selecting the correct type.

Additionally, valve cover gaskets play a vital role in preventing oil leaks and maintaining engine cleanliness. These gaskets must withstand high temperatures and pressures, and materials such as silicone or rubber are commonly used for their durability and flexibility. The National Institute for Automotive Service Excellence states that faulty gaskets can result in significant maintenance costs, emphasizing the need for precise gasket specifications to match engine requirements. Understanding the properties and applications of various gaskets ensures that automotive professionals can make informed choices, ultimately enhancing engine efficiency and longevity.

This chart illustrates the various types of automotive gaskets along with their specific applications in different engine types.

When selecting engine gaskets for your automotive needs, it's crucial to consider several key factors that influence both performance and longevity. Firstly, the material of the gasket plays a significant role in its durability and heat resistance. Common materials include rubber, metal, and composite options. Each has its specialties; for instance, metal gaskets are often used in high-performance applications due to their ability to withstand extreme temperatures and pressures.

Another essential factor is the gasket's thickness and compression capabilities. A gasket that is too thick may lead to improper sealing, while an overly thin gasket can be prone to failure. It's vital to consult your vehicle's specifications to ensure that you're choosing a gasket that meets the recommended standards.

**Tips:** Always verify the compatibility of gaskets with your engine type and its specific needs. Additionally, consider using original equipment manufacturer (OEM) parts for guaranteed quality and fit. Regularly inspect gaskets for wear, especially after major repairs, to ensure they maintain their sealing properties and prevent costly leaks.

| Gasket Type | Material | Temperature Resistance (°C) | Compatibility | Typical Applications |

|---|---|---|---|---|

| Head Gasket | MLS (Multi-Layer Steel) | 300 | Gasoline, Diesel | Engine Block to Cylinder Head |

| Valve Cover Gasket | Rubber or Silicone | 150 | Gasoline, Diesel | Valve Cover to Cylinder Head |

| Oil Pan Gasket | Felt or Rubber | 100 | Gasoline, Diesel | Oil Pan to Engine Block |

| Exhaust Manifold Gasket | Graphite | 600 | Gasoline, Diesel | Exhaust Manifold to Cylinder Head |

| Intake Manifold Gasket | Composite Material | 200 | Gasoline | Intake Manifold to Engine Block |

When selecting the right automotive gaskets for your engine, understanding the materials used in gasket manufacturing is crucial. Common materials include rubber, silicone, cork, and metal, each offering distinct benefits for various engine applications. According to the 2021 Automotive Gaskets Market Report, rubber gaskets are known for their excellent sealing properties and flexibility, making them ideal for low-pressure applications. In contrast, metal gaskets, particularly those made from aluminum or steel, are favored in high-temperature and high-pressure environments due to their durability.

Tips for optimizing gasket selection: always consider the specific environment in which the gasket will operate. For instance, if the engine experiences extreme heat, a silicone gasket will provide better resistance compared to traditional rubber. Furthermore, the integrity of the gasket is also influenced by the engine's design; thus, consulting with a gasket supplier can ensure compatibility based on material properties and engine specifications.

Another key material is cork, often used in oil pan gaskets due to its compressibility and ability to seal against irregular surfaces. A noteworthy statistic from the industry indicates that approximately 25% of automotive manufacturers are shifting towards composite materials, which combine the strengths of multiple materials, leading to improved performance and longevity in gasket applications. When choosing gaskets, always weigh the long-term cost benefits against the initial price, as investing in quality materials can reduce potential leaks and maintenance costs down the line.

When it comes to automotive gaskets, proper installation is critical for optimal engine performance. First, ensure that all mating surfaces are clean, flat, and free from debris. Any dirt or unevenness can cause leaks, compromising the effectiveness of the gasket. Use a suitable gasket sealing compound when recommended, but be cautious not to over-apply it, as too much can lead to choking the gasket and eventual failure. Following the manufacturer's torque specifications is vital; improper torque can result in gasket deformation or premature wear.

Maintaining automotive gaskets is just as important as their installation. Regularly check for signs of wear or damage, such as oil leaks or coolant seepage. Addressing these issues promptly can prevent more significant engine problems down the line.

Additionally, consider the type of gasket material; some materials are more resistant to certain fluids and temperatures than others. Understanding your vehicle's specific needs and the operational conditions will help in selecting not only the right gasket but also in ensuring its longevity through proper maintenance practices. Taking these steps can safeguard your engine's health and enhance its overall efficiency.