In the automotive industry, choosing the right automotive gaskets is crucial for ensuring optimal vehicle performance and longevity. A report from MarketsandMarkets indicates that the automotive gasket market is expected to reach $4.95 billion by 2025, driven by increasing vehicle production and advancements in gasket technology. Automotive gaskets play a vital role in sealing engine components, preventing leaks, and maintaining pressure within various systems. With the rising complexity of modern engines and strict emission regulations, selecting the appropriate gasket type can significantly impact efficiency and reliability. Whether you are replacing a head gasket, oil pan gasket, or exhaust gasket, understanding the different materials and designs available is essential for making an informed decision. By considering factors such as heat resistance, compatibility, and the specific requirements of your vehicle model, you can ensure that your engine operates smoothly and effectively.

In the automotive industry, choosing the right automotive gaskets is crucial for ensuring optimal vehicle performance and longevity. A report from MarketsandMarkets indicates that the automotive gasket market is expected to reach $4.95 billion by 2025, driven by increasing vehicle production and advancements in gasket technology. Automotive gaskets play a vital role in sealing engine components, preventing leaks, and maintaining pressure within various systems. With the rising complexity of modern engines and strict emission regulations, selecting the appropriate gasket type can significantly impact efficiency and reliability. Whether you are replacing a head gasket, oil pan gasket, or exhaust gasket, understanding the different materials and designs available is essential for making an informed decision. By considering factors such as heat resistance, compatibility, and the specific requirements of your vehicle model, you can ensure that your engine operates smoothly and effectively.

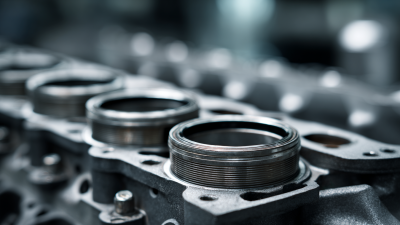

When it comes to automotive gaskets, understanding the different types can significantly influence the performance and longevity of your vehicle. Gaskets serve as critical components that create a seal between two or more surfaces in your engine, preventing leaks of fluids and ensuring proper compression. The primary types of automotive gaskets you’ll encounter include head gaskets, intake manifold gaskets, valve cover gaskets, and exhaust gaskets, each designed for specific applications and conditions.

Head gaskets, for instance, are crucial in maintaining the seal between the engine block and the cylinder head, preventing coolant and engine oil from mixing. Intake manifold gaskets, on the other hand, ensure that air and fuel mixtures flow smoothly into the engine. Valve cover gaskets protect the engine by sealing the valve cover and preventing oil leaks. Lastly, exhaust gaskets prevent exhaust gases from escaping the exhaust manifold, which is vital for efficient engine operation. By recognizing the purpose and function of each type of gasket, vehicle owners can make informed decisions when choosing replacements, ultimately leading to better performance and fewer repairs.

When selecting automotive gaskets for your vehicle, it’s essential to consider several key factors to ensure optimal performance and longevity. First and foremost, the material of the gasket plays a crucial role. Gaskets are typically made from materials such as rubber, metal, or composite. Each material has its unique advantages and is suited for specific applications. For instance, silicone gaskets provide excellent temperature resistance, making them ideal for high-heat environments, while metal gaskets offer superior strength for heavy-duty applications.

Another significant factor to consider is the thickness and compression rating of the gasket. A proper fit is vital to avoid leaks, which can lead to severe engine damage. Thick gaskets may be required for certain applications to maintain a proper seal, especially in high-pressure systems. Additionally, understanding the specific requirements of your vehicle's engine type and the service conditions it operates under can help you choose the right gasket. Always refer to the manufacturer’s specifications and guidelines to ensure compatibility and performance.

This chart illustrates key factors to consider when selecting automotive gaskets for your vehicle. Importance levels are rated from 0 to 100, showing that material selection is the most critical factor, followed closely by temperature resistance and pressure tolerance.

When selecting automotive gaskets, understanding the material types—rubber, cork, and metal—can significantly impact performance and longevity. Rubber gaskets, made from synthetic compounds like nitrile or neoprene, are highly flexible and resistant to fluids, making them ideal for applications involving oil and coolant. According to a report by the Automotive Gasket Association (AGA), rubber gaskets are favored in over 60% of modern engine designs due to their superior sealing capabilities and ease of installation.

Cork gaskets, traditionally used in older vehicles, offer a combination of compressibility and resilience. They provide decent thermal insulations but have been largely supplanted by advanced materials in new models. Data from IndustryWeek points out that while cork gaskets are still utilized in some applications, their market share has decreased to around 15% as manufacturers shift towards more durable alternatives.

Metal gaskets, often made of materials like steel or aluminum, are designed for high-pressure applications. Their strength and longevity make them essential in exhaust and cylinder head applications. A recent study by the Society of Automotive Engineers (SAE) highlights that the use of metal gaskets has increased by 25% among high-performance vehicles, reflecting their critical role in optimizing engine efficiency and effectively managing thermal expansion. Knowing these differences can guide vehicle owners in making informed decisions when replacing or upgrading their gaskets.

When selecting automotive gaskets, evaluating compatibility with your engine specifications is crucial. Gaskets serve as seals between different engine components, preventing leaks and ensuring optimal performance. The right gasket must match not only the engine's dimensions but also the materials used in its construction. According to a report by MarketsandMarkets, the global automotive gasket market is projected to reach $4.12 billion by 2025, highlighting the growing importance of choosing quality gaskets tailored to specific vehicle models.

Incompatibility can lead to significant engine issues, such as overheating and oil leaks. Data from the Society of Automotive Engineers indicates that approximately 60% of engine failures are associated with improper sealing, underscoring the need for precise fitment. Engine gaskets are available in various materials, including rubber, metal, and composite, each offering different performance characteristics. For example, composite gaskets provide improved thermal stability, making them suitable for high-performance engines. It’s essential to consult the vehicle manufacturer's specifications or a trusted automotive expert to ensure that the gaskets selected meet the required criteria for your engine's performance and durability.

When it comes to purchasing automotive gaskets, the age-old dilemma of cost versus quality often arises. It's crucial to understand that while budget-friendly options may seem appealing, opting for lower-quality gaskets can lead to significant long-term costs. These inferior products often wear out more quickly, causing potential leaks and failures that can require expensive repairs and replacements down the line. Investing in higher-quality gaskets not only enhances the performance of your vehicle but also ensures its longevity.

To make an informed decision, consider factors such as the material of the gasket, the manufacturer’s reputation, and any specific requirements for your vehicle model. High-quality gaskets are typically made from robust materials like graphite or copper and are designed to withstand extreme temperatures and pressures. While they may present a higher upfront cost, their durability and reliability can save you money on repairs and maintenance in the future. Therefore, striking the right balance between cost and quality is essential for ensuring your vehicle operates optimally.