In today's manufacturing landscape, "Stainless Steel Stamped Parts" are essential for various projects. According to expert John Smith, a renowned materials engineer, "The durability and versatility of stainless steel parts cannot be overstated." This statement rings true for many industries, from automotive to aerospace.

Stainless steel stamped parts offer strength and resistance to corrosion. The unique properties of stainless steel make these components particularly valuable. However, not all manufacturers fully understand the challenges and costs involved. Quality control is crucial, as subpar parts can lead to costly delays and project setbacks.

Choosing stainless steel stamped parts may seem straightforward, but it requires careful consideration. Each project has distinct requirements that must be met. Some may overlook the potential savings of investing in high-quality components. In the long run, these savings can make a significant difference. Understanding these nuances helps in making informed choices that impact project success.

Stainless steel is a popular choice for manufacturing stamped parts due to its durability and resistance to corrosion. A recent industry report indicates that stainless steel features over 85% corrosion resistance in harsh environments. This property makes it ideal for applications in automotive, aerospace, and medical devices. Projects needing longevity can rely on stainless steel to significantly reduce maintenance costs and increase product lifespan.

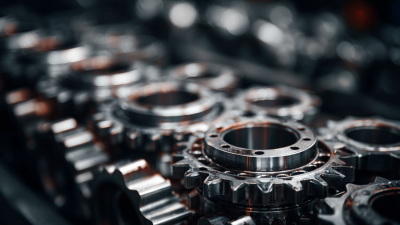

The strength of stainless steel is another advantage. In lab tests, stainless steel stamped parts have shown tensile strength exceeding 200,000 psi. This high strength enables thinner parts while maintaining structural integrity. Thinner parts can lead to weight savings in applications such as vehicle manufacturing. However, sourcing high-quality stainless steel can be challenging and affects production timelines. Careful selection is essential for successful outcomes.

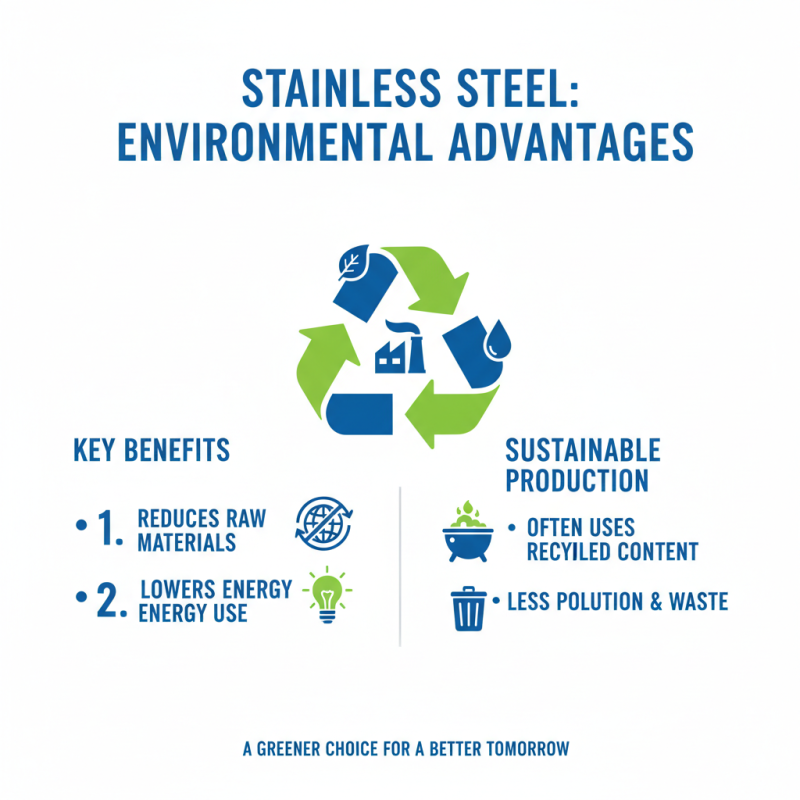

Furthermore, stainless steel is eco-friendly and recyclable. Studies show that over 70% of stainless steel produced is recycled. This aligns with growing sustainability demands in manufacturing. Yet, fabricating with stainless steel requires skill. Mistakes in stamping can lead to material waste, which poses challenges for budgeting. Learning curves are common, especially for projects with complex designs.

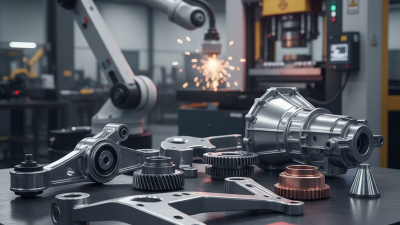

Stainless steel stamped parts are essential in various industries. Their durability and resistance to corrosion make them suitable for demanding environments. Many manufacturers in automotive, aerospace, and medical sectors rely on these parts. They offer lightweight solutions with outstanding strength.

In the automotive industry, stainless steel parts contribute to vehicle safety. They are used in brackets, chassis components, and exhaust systems. The ability to withstand harsh conditions is vital here. In healthcare, stainless steel stamped parts are critical in medical devices. They ensure hygiene and longevity. One flaw to consider is their cost. They may be more expensive upfront than alternatives, but the long-term benefits often outweigh the initial investment.

**Tips:** When choosing materials, weigh their performance against costs. It’s crucial to identify your project requirements early. Testing prototypes can reveal unexpected issues. Testing is vital to ensure that parts fit correctly in assemblies. Always advocate for quality checks during the manufacturing process. Remember, choosing the right part can significantly affect your project's success.

| Industry | Key Applications | Benefits of Stainless Steel |

|---|---|---|

| Automotive | Brackets, trim pieces, engine components | Corrosion resistance, strength, and durability |

| Aerospace | Structural components, fasteners | Lightweight, high strength-to-weight ratio |

| Medical | Surgical tools, equipment components | Biocompatibility, sterilizability |

| Food and Beverage | Processing equipment, containers | Hygienic properties, resistance to acids and cleaning agents |

| Electronics | Connectors, housings, thermal components | Electromagnetic shielding, thermal conductivity |

When considering materials for your project, the cost-effectiveness of stainless steel stamped parts emerges prominently. A recent industry report shows that stainless steel parts can cost up to 30% less than equivalent aluminum or plastic options over time. While the initial investment may seem higher, the durability and low maintenance of stainless steel offset these costs significantly.

Stainless steel is resistant to corrosion and wear, enhancing its longevity. The average lifespan of stainless steel parts can exceed 20 years. Comparatively, plastic parts often degrade or become brittle within a decade. This factor becomes crucial when estimating long-term project expenses. Companies that overlook this aspect often face costly replacements.

**Tips:** Ensure to assess the total lifecycle costs of materials. Compare not only the purchase price but also the maintenance and replacement aspects.

However, some projects may require flexibility and lightweight components. In such cases, the rigidity of stainless steel could be a drawback. The decision depends on the specific requirements of your project. Balancing cost and performance should be pivotal in your selection process.

Stainless steel is often chosen for its impressive durability and remarkable corrosion resistance. This alloy contains chromium, which forms a protective layer on its surface. This layer helps prevent rust and degradation, even in harsh environments. Imagine a kitchen sink that stays shiny and new – that’s the magic of stainless steel.

However, not all stainless steel parts are created equal. Depending on the project, the grade of stainless steel can affect performance. Some grades are more resistant to certain chemicals or temperatures than others. It's essential to choose the right grade for your specific needs.

**Tips:** Always consider environmental factors when selecting stainless steel parts. Exposure to saltwater or acidic substances can influence the longevity. Test samples in your working conditions if possible. It’s a learning process. Sometimes, the choices we make won’t yield the expected results. This reflection can lead to better decisions in future projects.

Stainless steel has gained popularity for its numerous advantages. One significant aspect is its environmental impact. The production of stainless steel often involves recycled materials. Thus, it reduces the need for raw resources. Using recycled steel lessens energy consumption during manufacturing.

However, the sustainability of stainless steel production must be approached cautiously. Not all stainless steel is created equally. The energy-intensive processes can lead to higher carbon emissions. This raises questions about how we measure sustainability in materials.

**Tips:** When selecting materials, look for suppliers specializing in recycled content. Every small choice can contribute to a more eco-friendly project. Researching the lifecycle of stainless steel is essential. Understanding the full impact helps in responsible decision-making. Remember, not all components from stainless steel may offer the same environmental benefits.