In today’s manufacturing landscape, precision and durability matter. Many companies seek materials that meet high standards without breaking the bank. Stainless Steel Stamped Parts have emerged as a go-to solution. These components boast both strength and aesthetic appeal, making them suitable for various applications.

Choosing Stainless Steel Stamped Parts means investing in quality. Their resistance to corrosion and wear ensures longevity. However, sourcing these parts may present challenges. Not every supplier delivers the same quality or reliability.

Manufacturers must evaluate options carefully. Some may overlook the nuances of thickness or finish, leading to issues down the line. Consider the specific needs of your project. Understanding these details is crucial for success. Ultimately, Stainless Steel Stamped Parts can elevate your production process, but informed choices are key.

Stainless steel stamped parts are increasingly favored in manufacturing due to their durability and resistance to corrosion. They can withstand harsh environments without degrading. This makes them ideal for various applications, from automotive to aerospace. The strength of stainless steel ensures that the parts perform reliably over time.

Cost-effectiveness is another significant advantage. While initial costs may be higher, the long lifespan reduces the need for frequent replacements. Consider the long-term savings when calculating overall expenses. However, manufacturers must ensure they invest in high-quality materials to maximize these benefits. Subpar parts can lead to failures, negating cost advantages.

Design flexibility is also a key consideration. Stainless steel can be easily shaped into complex designs, allowing for innovative products. Engineers need to collaborate closely during the design phase to avoid pitfalls. If communication falters, a well-designed part can become a functional failure. Overall, stainless steel stamped parts offer a blend of longevity, cost savings, and versatility, making them a smart choice for many manufacturing projects.

Stainless steel is a crucial material in manufacturing, especially for stamped parts. Its durability is unmatched, making it ideal for tough industrial applications. According to a report by the International Stainless Steel Forum, the global stainless steel market is projected to reach USD 187 billion by 2026. This reflects its growing importance in various sectors.

One standout feature of stainless steel is its corrosion resistance. In industries like automotive and aerospace, components face harsh conditions. A study from the American Iron and Steel Institute highlights that stainless steel parts can last up to 100 years in a corrosive environment. However, not all stainless steel grades offer the same resistance. Selecting the appropriate grade is critical and can be a source of confusion for manufacturers.

Another noted characteristic is its strength-to-weight ratio. Stainless steel is both strong and lightweight, promoting energy efficiency. The Metal Industries Institute notes that lightweight components can reduce fuel consumption in vehicles. But, over-optimizing for weight can compromise structural integrity. This balance between strength and weight is a common topic of discussion in engineering circles.

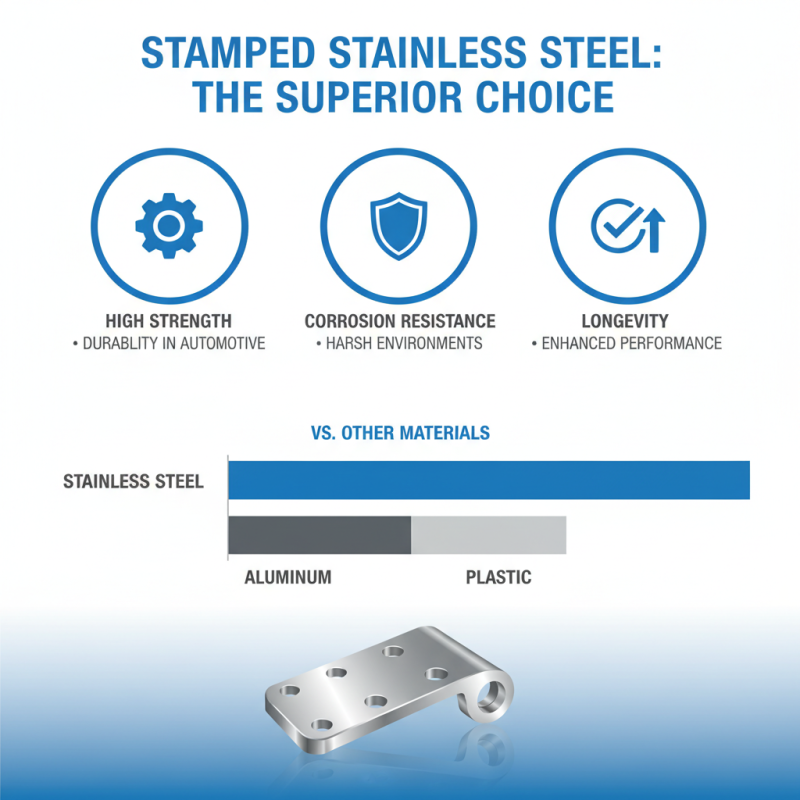

This bar chart illustrates the key characteristics of stainless steel for industrial applications. The data represents the relative importance of various properties, including Corrosion Resistance, Strength, Ductility, and Cost-Effectiveness.

Stainless steel is a popular choice for stamped parts due to its remarkable properties. It offers high strength and excellent corrosion resistance. When compared to other materials like aluminum or plastic, stainless steel performs better in harsh environments. For instance, in automotive applications, its durability enhances the longevity of components.

However, there are downsides. Stainless steel can be heavier than alternatives, which may not be suitable for every application. Costs are also higher. These factors may lead manufacturers to reconsider their choices. Analyzing the specific needs is crucial.

Tips: Consider the environment where the part will be used. If it’s exposed to moisture or chemicals, stainless steel stands out. Also, factor in the weight limits of your application. Sometimes, a lighter alternative may be more beneficial, even if it compromises durability. Take time to explore all options. Balancing performance with cost can be challenging yet worthwhile.

When considering manufacturing needs, stainless steel stamped parts present a compelling option. The cost-effectiveness of these components is underscored by data from industry reports. For instance, stainless steel can reduce maintenance costs by 30% due to its corrosion resistance. This property extends the lifecycle of parts, often exceeding 20 years in various applications. Such longevity can significantly lower overall production costs.

Moreover, the initial investment in stainless steel can be offset by its durability. According to a recent survey, more than 60% of manufacturers noted that stainless steel parts require less frequent replacement. This minimizes downtime and production intervals. The upfront cost is often justified, as stainless steel components can withstand extreme conditions and harsh environments.

However, it's essential to recognize potential limitations. Not all applications benefit from stainless steel’s features. Some projects may require additional processing, which can add to expenses. Furthermore, sourcing can present challenges that impact timelines. Careful consideration and analysis are necessary to ensure that the choice of materials aligns with project goals.

Stainless steel stamped parts are essential across multiple industries. These parts are vital in automotive, aerospace, and medical sectors. According to a recent industry report, the global market for stamped metal components is expected to reach $250 billion by 2025. This rapid growth highlights their increasing significance.

In the automotive industry, stainless steel stamped parts ensure durability and corrosion resistance. These features are crucial for vehicle longevity. A study from the American Society of Mechanical Engineers revealed that corrosion-related issues account for about 20% of vehicle failures. The lightweight nature of stainless steel contributes to fuel efficiency as well. However, challenges remain in achieving the perfect balance between weight and strength.

The medical sector also heavily relies on stainless steel stamped parts. Devices must meet stringent safety standards, making reliability paramount. For example, surgical instruments often require precise manufacturing to avoid malfunctions. Yet, even minor deviations in production can lead to serious consequences. A report by the FDA noted that improper manufacturing processes could jeopardize patient safety, illustrating the need for continuous quality improvement. Thus, while stainless steel offers numerous benefits, addressing production flaws is critical.