In the ever-evolving landscape of manufacturing, the demand for high-quality Stamping Die Parts has surged, presenting an undeniable opportunity for global buyers to enhance efficiency in their production processes. According to industry reports, the global metal stamping market is expected to reach $270 billion by 2025, driven by advancements in technology and materials. The integration of premium stamping die parts not only reduces production time but also minimizes waste, ultimately leading to significant cost savings. Furthermore, studies show that using precision-engineered stamping die components can improve product quality and consistency, thereby enhancing customer satisfaction. As manufacturers strive to meet the increasing demands for customization and rapid delivery, investing in superior stamping solutions becomes not just beneficial but essential for staying competitive in today's market.

In the ever-evolving landscape of manufacturing, the demand for high-quality Stamping Die Parts has surged, presenting an undeniable opportunity for global buyers to enhance efficiency in their production processes. According to industry reports, the global metal stamping market is expected to reach $270 billion by 2025, driven by advancements in technology and materials. The integration of premium stamping die parts not only reduces production time but also minimizes waste, ultimately leading to significant cost savings. Furthermore, studies show that using precision-engineered stamping die components can improve product quality and consistency, thereby enhancing customer satisfaction. As manufacturers strive to meet the increasing demands for customization and rapid delivery, investing in superior stamping solutions becomes not just beneficial but essential for staying competitive in today's market.

In today's competitive manufacturing landscape, the efficiency of production processes is paramount.

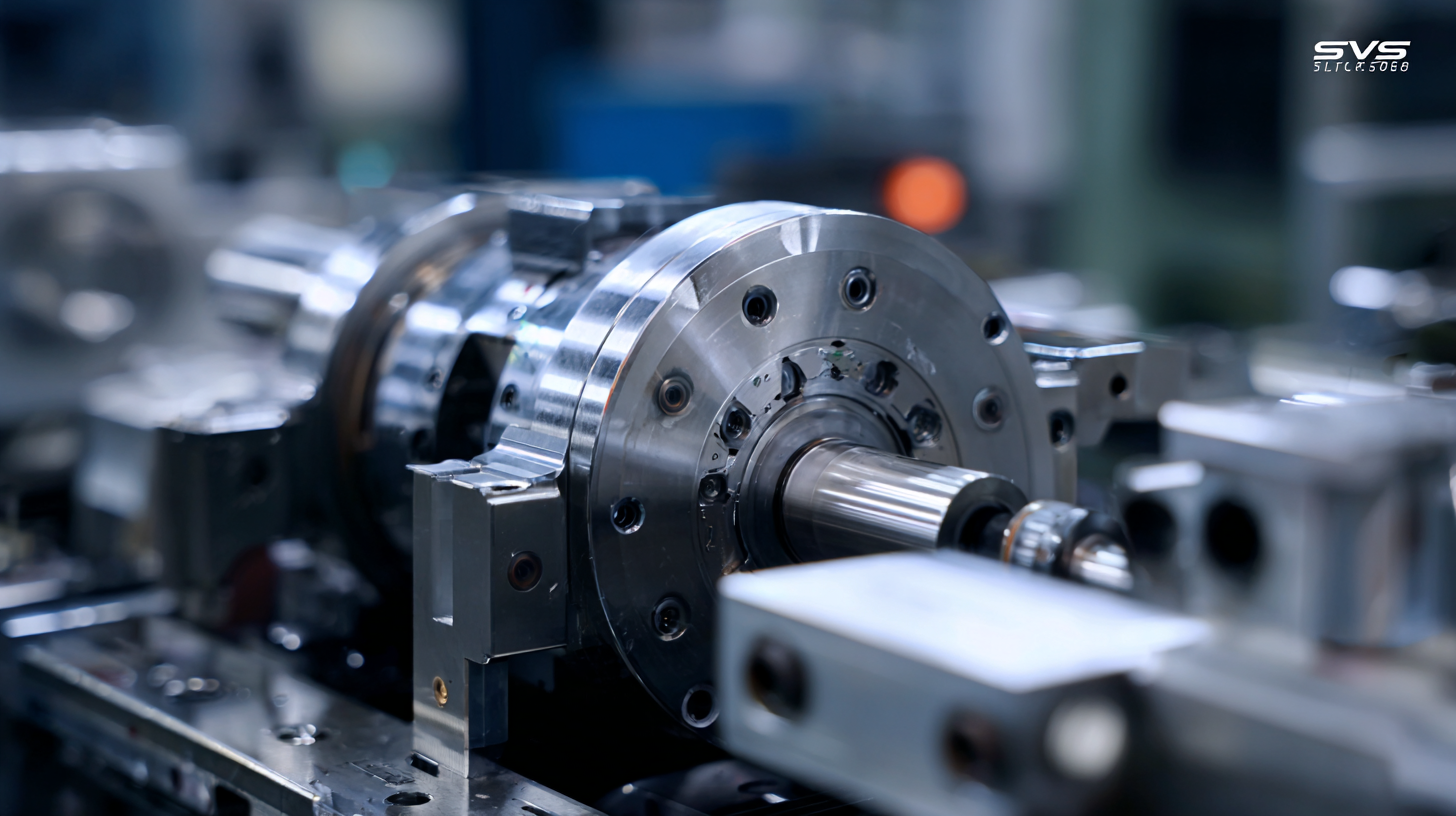

Premium stamping die parts are revolutionizing global manufacturing by enhancing precision and reducing cycle times.

With the increasing demand for high-quality components, particularly in sectors such as automotive and aerospace,

the advantages of using superior stamping die parts cannot be overstated. They ensure a high level of accuracy in the production of complex shapes,

which is essential for meeting the stringent requirements of modern engineering applications.

Additionally, the advancements in the metal stamping industry, driven by innovations in materials and technology,

are streamlining operations across various sectors. As highlighted in recent market analyses, the rising interest in press hardening steel,

especially in automotive applications, reflects a trend towards more efficient and durable manufacturing processes.

The integration of premium stamping die parts not only supports these advancements but also contributes to significant cost savings and waste reduction.

By investing in high-quality tooling, global manufacturers can achieve greater efficiency and adaptability in an ever-evolving market landscape.

When sourcing stamping die components, global buyers should prioritize essential features that ensure the effectiveness and longevity of their tools. High-quality stamping die parts, on average, enhance production efficiency by 15-25%, as reported by the Precision Metalforming Association. This efficiency gain is primarily attributed to the precision engineering within premium components, which results in fewer production errors and reduced downtime during manufacturing processes.

Moreover, the durability of these components significantly impacts operational costs. According to a recent industry study, investing in high-quality stamping die parts can decrease maintenance expenditures by up to 30%. Buyers should pay close attention to the materials used, such as premium tool steels and advanced coatings, which not only improve wear resistance but also contribute to a longer tool lifecycle. Features like precision-made ejector pins and bushings are crucial, as they enhance the overall functionality of the die, ensuring consistent stamping results and minimizing scrap rates. Prioritizing these key attributes can lead to streamlined operations and higher profitability.

Investing in premium stamping die parts offers significant long-term gains that extend far beyond initial cost considerations. A comprehensive cost-benefit analysis reveals that while the upfront expense may be higher, the longevity and improved efficiency they bring can lead to substantial savings over time. High-quality die parts are designed to outperform their standard counterparts, resulting in reduced wear and tear, less downtime, and lower maintenance costs. This is particularly crucial in a competitive manufacturing landscape where operational efficiency directly impacts profitability.

Moreover, integrating environmental, social, and corporate governance (ESG) principles into procurement decisions enhances value creation. Premium die parts often align with sustainable manufacturing practices, which not only mitigate risks associated with supply chain disruptions but also contribute to a company’s reputation and compliance with evolving regulatory standards. As global buyers seek to optimize their production processes, understanding the long-term financial and ethical implications of their investments in die parts becomes essential for achieving sustainable growth and profitability.

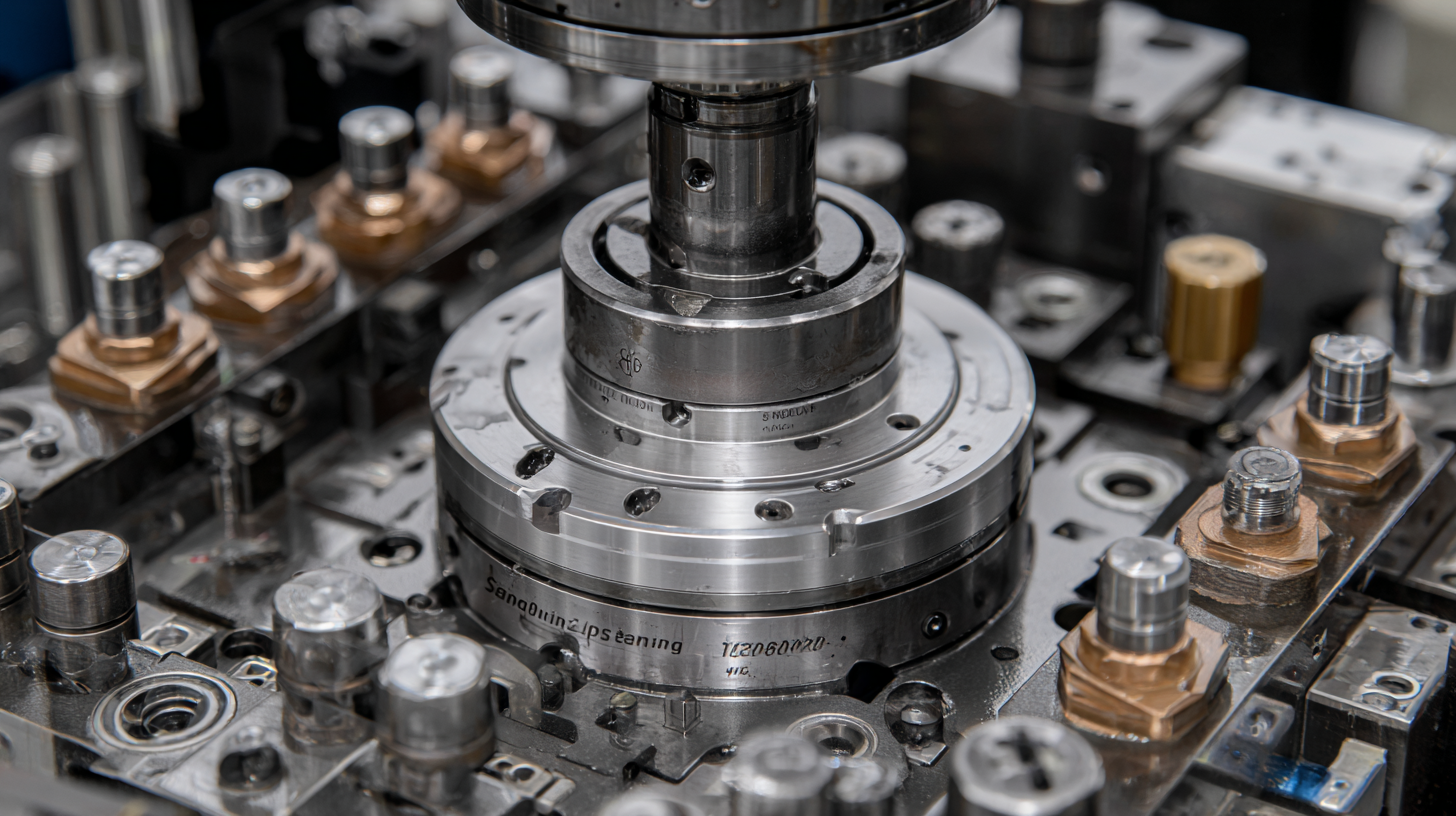

In today’s rapidly evolving manufacturing landscape, enhancing production accuracy is paramount. The integration of advanced stamping die solutions is a key factor in achieving this goal, especially as industries strive for greater efficiency and precise component fabrication. Recent advancements, such as machine learning algorithms optimized for sheet metal stamping, have revolutionized the way manufacturers approach production. These technologies leverage data-driven insights to increase precision, reducing waste and improving the overall quality of stamped parts.

Additionally, the ongoing collaboration between leading industries further underscores the importance of precision in manufacturing processes. The automotive sector, in particular, demands components that not only meet stringent safety standards but also contribute to more sustainable vehicle designs. The shift towards lighter materials, driven by the pressing need for fuel efficiency and eco-friendliness, mandates advanced stamping die solutions that can deliver the required accuracy and durability. As the market for precision metal stamping continues to grow, investing in premium stamping die parts is essential for global buyers seeking to enhance their production capabilities.

This chart illustrates the impact of premium stamping die parts on production accuracy, with data representing improvements in efficiency across various production metrics.

When seeking premium stamping die parts, selecting the right suppliers is critical for maximizing efficiency and ensuring product quality. Start by identifying suppliers with extensive experience in the field. Their proven track record is often indicative of reliability and the capacity to deliver superior products. You may also want to consider those who offer customization options, as tailored solutions can significantly enhance the performance of your stamping operations.

Another key guideline is to assess the supplier's technology and manufacturing capabilities. Suppliers that invest in advanced machinery and technology are more likely to produce precise and durable die parts. Additionally, clear communication channels can streamline the procurement process, allowing for adjustments and feedback to be exchanged swiftly. It's beneficial to seek suppliers who prioritize transparency regarding their production processes, as this fosters trust and collaboration in the long run.