In the world of metalworking, the angle grinder disc metal plays a crucial role. It is an essential tool for cutting, grinding, and polishing metal surfaces. According to a recent industry report by Smith & Associates, the demand for angle grinder discs has surged by 25% in the last year. This growth highlights the importance of these tools in various sectors, from construction to automotive.

Expert John Reynolds, a prominent figure in the metalworking industry, emphasizes the significance of using the right angle grinder disc metal. He states, "Choosing the right disc can make or break your project." This reflects the critical nature of proper tool selection. Many professionals overlook certain details, such as disc material and grit size, which can lead to inefficiency or even damage to materials.

With the rise in usage, there is a growing need for education on angle grinder discs. Many users are unaware of the different types available and their specific applications. Understanding these nuances is key to achieving optimal results. The relationship between the right disc and successful metalwork cannot be understated.

An angle grinder disc is a crucial tool accessory for metalworking. It allows for cutting, grinding, and polishing various metal surfaces. These discs come in different types and sizes, tailored to specific tasks.

For example, cutting discs are thinner and designed for slicing through metal quickly. In contrast, grinding discs are thicker and meant for smoothing rough edges.

When selecting a disc, it's vital to consider the material being worked on. Not all discs are suitable for every type of metal. Some might wear out faster than others. It's easy to overlook disc compatibility, leading to inefficient work or even safety hazards. Regular inspection of the disc is necessary as well. Noticing signs of wear can prevent accidents and improve final results.

Using an angle grinder disc requires attention to detail. Proper technique is key to achieving a clean finish. Improper usage can lead to mistakes, like uneven cuts or burns on the metal surface. One must also think about safety precautions, like wearing protective gear. Skipping these steps can lead to injury. Balancing speed and finesse is a constant challenge with an angle grinder.

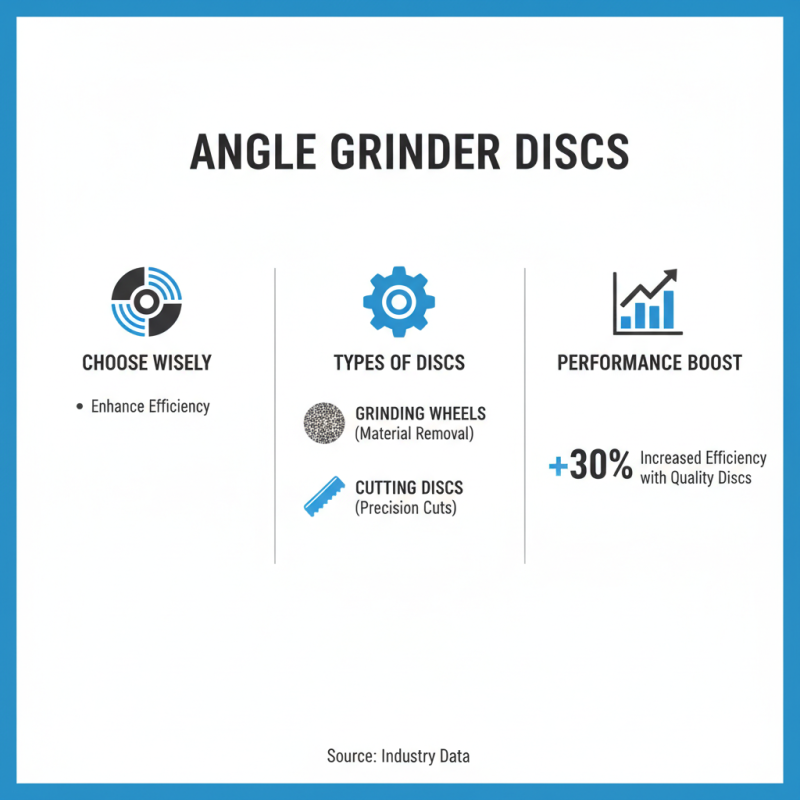

When it comes to working with metal, choosing the right angle grinder disc is crucial. Different types of discs serve specific purposes. For instance, grinding wheels are ideal for removing large amounts of material quickly. Data shows that using a high-quality grinding disc can enhance efficiency by up to 30%.

Cutting discs provide precise cuts in metal materials. They are thinner and designed to slice through metal sharply. Research indicates that the right cutting disc can lead to cleaner edges and less heat generation during cuts, reducing the risk of warping. On the other hand, flap discs offer versatility. They combine grinding and finishing in one tool. This means effective material removal alongside a smoother surface finish.

However, not all discs are created equal. Some may wear down quicker than others, requiring more frequent changes. Users should be cautious and ensure they choose the right type for their tasks. Overlooking the specifications can lead to inefficiencies. Understanding disc composition and intended use is essential for optimal performance.

Selecting the right angle grinder disc for metalworking requires careful consideration. There are many options available, and each serves a specific purpose. For instance, cutting discs are ideal for slicing through metal. They are thin and make clean cuts but can wear down quickly.

Flap discs provide a different approach. They combine grinding and finishing in one tool. These discs have overlapping flaps of abrasive material. They help create a smooth surface but might not cut as efficiently as a thinner disc. If your project involves more detailed work, a flap disc could be a better choice.

It’s also crucial to assess the material you are working with. Ferrous and non-ferrous metals require different types of discs. Using the wrong disc can lead to poor results. Experimenting with different discs may lead to unexpected outcomes. Don’t shy away from making mistakes. Each trial helps refine your technique and choice of tools.

When using an angle grinder disc for metal, safety is paramount. According to a 2022 industry report, nearly 20% of accidents in metalworking involve hand-held power tools. Proper precautions can significantly reduce these risks.

Always wear personal protective equipment (PPE). This includes safety goggles, gloves, and sturdy footwear. Loose clothing can be a hazard, so opt for fitted gear. Maintain a clean workspace to prevent tripping or falling objects, which can lead to serious injuries. Ensure that the angle grinder is well-maintained and that the disc is correctly attached.

Tips: Check your angle grinder for damage before use. A faulty tool can lead to significant injury. Also, be aware of your surroundings. Ensure no flammable materials are nearby. It’s crucial to work in a well-ventilated area to avoid fumes or sparks.

Lastly, stay focused while working. Distractions can lead to mistakes. A moment of inattention can result in severe injuries. Always keep both hands on the tool. Remember, safety isn’t just a guideline; it’s a necessity in metalwork.

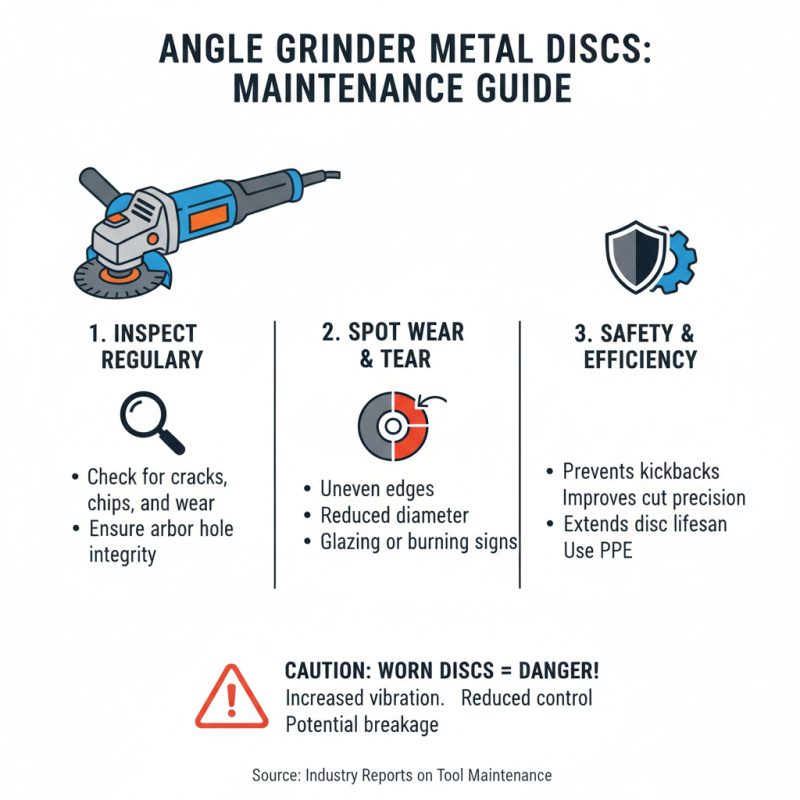

Angle grinder discs for metal use require careful maintenance to ensure optimal performance. According to industry reports, improperly maintained discs can lead to reduced cutting efficiency and potential safety hazards. Regularly inspecting the disc for wear is crucial. A worn-out disc can lead to increased vibration and less precision in cuts.

Cleaning the discs after each use is equally important. Dust and metal shavings can accumulate, affecting the disc's lifespan. Industry statistics reveal that proper cleaning can extend the life of a disc by up to 30%. Use a soft brush or cloth to remove debris. Avoid using harsh chemicals, as they can damage the disc.

Storing angle grinder discs correctly can also impact their longevity. Storing them in a damp environment can lead to rusting. A cool, dry place is ideal. Remember, even a small amount of neglect can lead to significant problems. Reflection on these maintenance practices can lead to more efficient and safer use of angle grinder discs.